11

English (US)

6. Control mode and signals

6.1 Internal control principles

GRUNDFOS UPML and UPMXL AUTO automatically control the

differential pressure by adjusting the pump performance to the

actual heat demand, without the use of external components.

Two different control modes are available:

6.1.1 GRUNDFOS AUTOADAPT

The Grundfos AUTOADAPT function enables the circulator to

control the pump performance automatically within a defined

performance range.

• Adjusting the pump performance to the size of the system.

• Adjusting the pump performance to the variations in load over

time.

Two different control modes are available for Grundfos

AUTOADAPT:

6.2 External control principles

6.2.1 PWM

GRUNDFOS UPML and UPMXL PWM circulators are controlled

via a digital low-voltage pulse-width modulation (PWM) signal

which means that the speed of rotation depends on the input

signal. The speed changes as a function of the input profile.

These communication signals are standardized in the VDMA

Einheitsblatt 24224 “Wet runner circulating pumps - Specification

of PWM control signals”.

Digital low-voltage PWM signal

The square-wave PWM signal is designed for a 100 to 4000 Hz

frequency range. The PWM signal is used to select the speed

(speed command) and as feedback signal. The PWM frequency

of the feedback signal is fixed at 75 Hz in the pump.

Duty cycle: d % = 100 x t/T

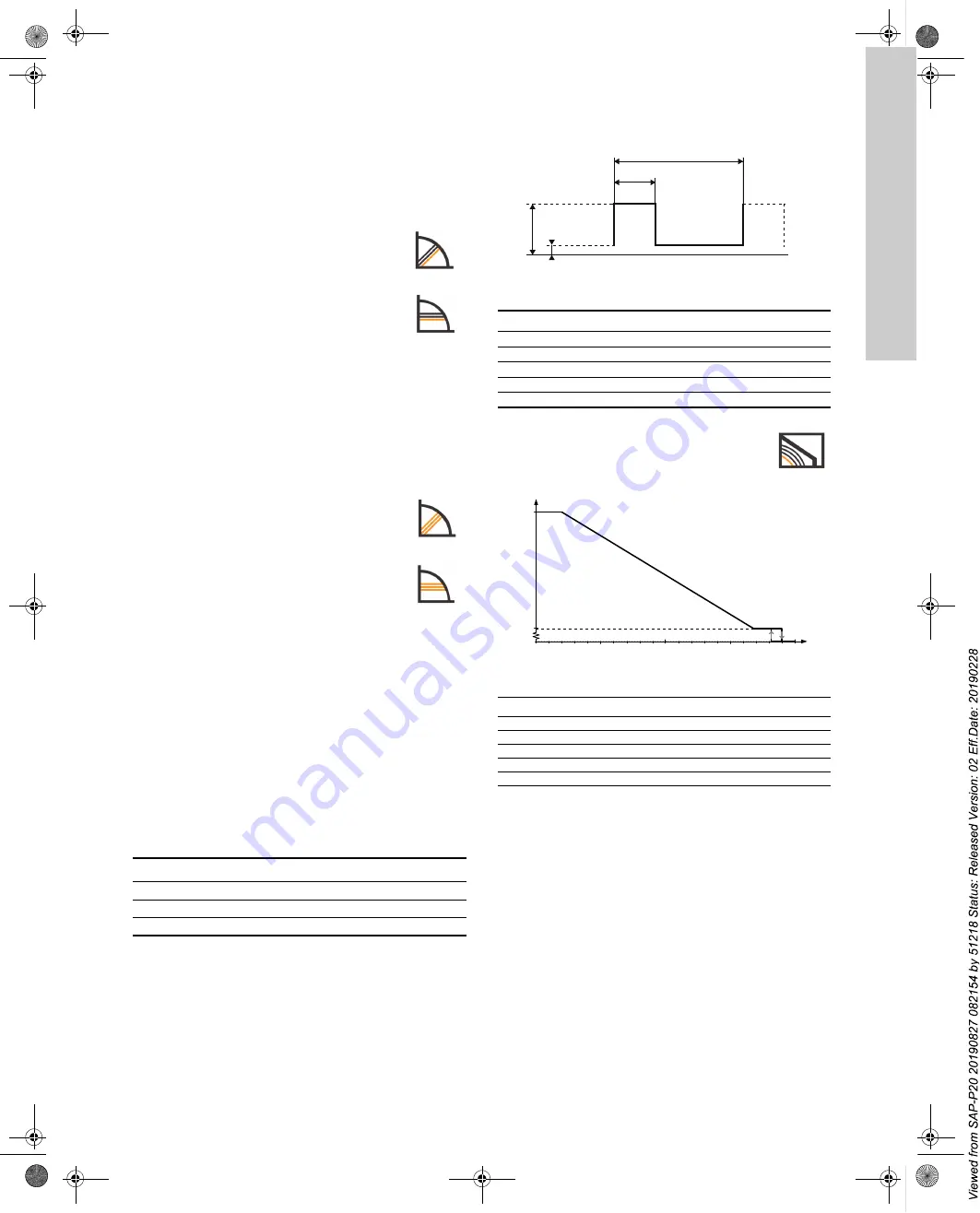

Fig. 11

PWM signal

Fig. 12

PWM input profile A (heating)

PWM feedback signal - Power consumption

PWM feedback signal to system control: power consumption and

various alarms such as under-voltage warning, under-voltage,

stop, locked rotor, internal failure and confirmation of standby

mode.

Proportional Pressure

The differential pressure increases at increased

flow.

Constant Pressure

The differential pressure is constant.

Proportional Pressure AUTOADAPT

In proportional pressure AUTOADAPT, the circulator

is set to proportional-pressure control.

Constant Pressure AUTOADAPT

In constant pressure AUTOADAPT, the circulator is

set to constant-pressure control.

Example

Rating

T = 2 ms (500 Hz)

U

IH

= 4-24 V

t = 0.6 ms

U

IL

≤

1 V

d %= 100 x 0.6 / 2 = 30 %

I

IH

≤

10 mA (depending on U

IH

)

TM

04 99

11

02

11

Abbreviation

Description

T

Period of time [sec.]

d

Duty cycle (t/T)

U

iH

High-level input voltage

U

iL

Low-level input voltage

I

iH

High-level input current

PWM input signal profile A (heating)

At low PWM signal percentages, the circulator

speed is high for safety reasons.

TM0

7 057

9 041

8

PWM input signal [%] Pump status

≤

10

Maximum speed: Max.

> 10 /

≤

84

Variable speed: Min. to max.

> 84 /

≤

91

Minimum speed: Min.

> 91 /

≤

95

Hysteresis area: On/off

> 95 /

≤

100

Standby mode: Off

T

t

U

iH

U

iL

5

10

20

30

40

50

60

70

80

90

100

Max.

Min.

Stop

UPMM_UPML_UPMXL_US.book Page 11 Tuesday, February 26, 2019 10:18 PM

Summary of Contents for UPML

Page 2: ...2 UPMM_UPML_UPMXL_US book Page 2 Tuesday February 26 2019 10 18 PM...

Page 16: ...16 UPMM_UPML_UPMXL_US book Page 16 Tuesday February 26 2019 10 18 PM...

Page 17: ...17 UPMM_UPML_UPMXL_US book Page 17 Tuesday February 26 2019 10 18 PM...

Page 18: ...18 UPMM_UPML_UPMXL_US book Page 18 Tuesday February 26 2019 10 18 PM...