8

2011

COIN

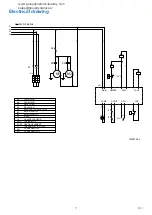

The cabinet can be connected to a booking system. To acti-

vate the function, set the parameter in position “ON”. To start a

programme, a connection to the control board’s COIN-contact

is needed.

SIGNAL TYPE

This parameter is only visible if COIN is activated. COIN is used

when the cabinet is connected to a booking system. Choose

position depending on which type of signal the booking system

is sending. “PLS” stands for pulse and means that the cabinet

is booked per drying period. One pulse gives one drying period.

“N-O” is chosen when the signal is either on or off. The current

programme will always run until finished even if the signal is

broken during the programme.

WORK TIME

The parameter shows the total amount of hours the cabinet

has been on. It is also memorized if the electricity to the control

board is broken.

TEST LOOP

Start the test programme by changing the parameter to “ON”.

The programme can be used to control the components in the

cabinet. Parts are activated as follows: To go to the next step,

press arrow button. The programme goes automatically to the

next level after 30 seconds.

1. Fans connected to FAN1

2. External fan connected to FAN2 (optional)

3. Heating on

4. All segments on LCD-display are lit and the background

light flashes

5. The temperature sensor shows current temperature

6. The humidity sensor shows current air humidity

CLEAR E-CODE

Is used to erase an e-code in the display, after the problem has

been solved. Press the right arrow button.

Disp Reason

Activity

T1

Control board gets no

signal from the tempera-

ture sensor.

Control that the sensor is

connected correctly on

the main control board

and that the cable from

the sensor to the board is

intact.

OH

The control board’s elec-

tronically overheat protec-

tion has been activated.

The error code is gener-

ated if the temperature is

risen above 100ºC, twice

within 30 minutes.

Control that the fan mo-

tors are working as they

should. Also control the

temperature sensor and

that the cable from the

board is intact.

HU

The control board gets no

signal from the humidity

sensor.

Control that the sensor is

connected correctly on

the main control board

and that the cable from

the sensor to the board is

intact.

Error codes

www.groupdynamics-laundry.com