Model T32859 (Mfd. Since 08/21)

-3-

Safety & Correct Use

Storage

DO NOT exceed table weight capacity of

350 lbs. Sudden change in dynamic load

at maximum weight capacity could cause

table to tip or collapse, resulting in serious

personal injury or property damage.

•

Do not apply an unbalanced load.

•

Keep unsupervised children away from the

table.

•

Do not stand or climb on the table.

•

Do not use in wet or damp locations.

•

Do not leave rags or other items that are

damp with water, oil, paint, or solvents on the

table.

•

Set up the table in a well-ventilated area

where there are no hazardous or combustible

materials that could ignite during welding

operations.

•

While using an electric welder, the welder

must be grounded to either the workpiece

or the table before the welding operation.

If grounding to the table, the workpiece

must contact the table so the current may

flow through the workpiece to the grounding

clamp and close the welding circuit. Ensure

there is insulation between the operator and

the electric current (a dry rubber mat, rubber

gloves, etc.).

•

Lubricate the hinge pins holding the legs

together and the shoulder screws attaching

the legs to the frame with light machine oil if

folding the table becomes difficult.

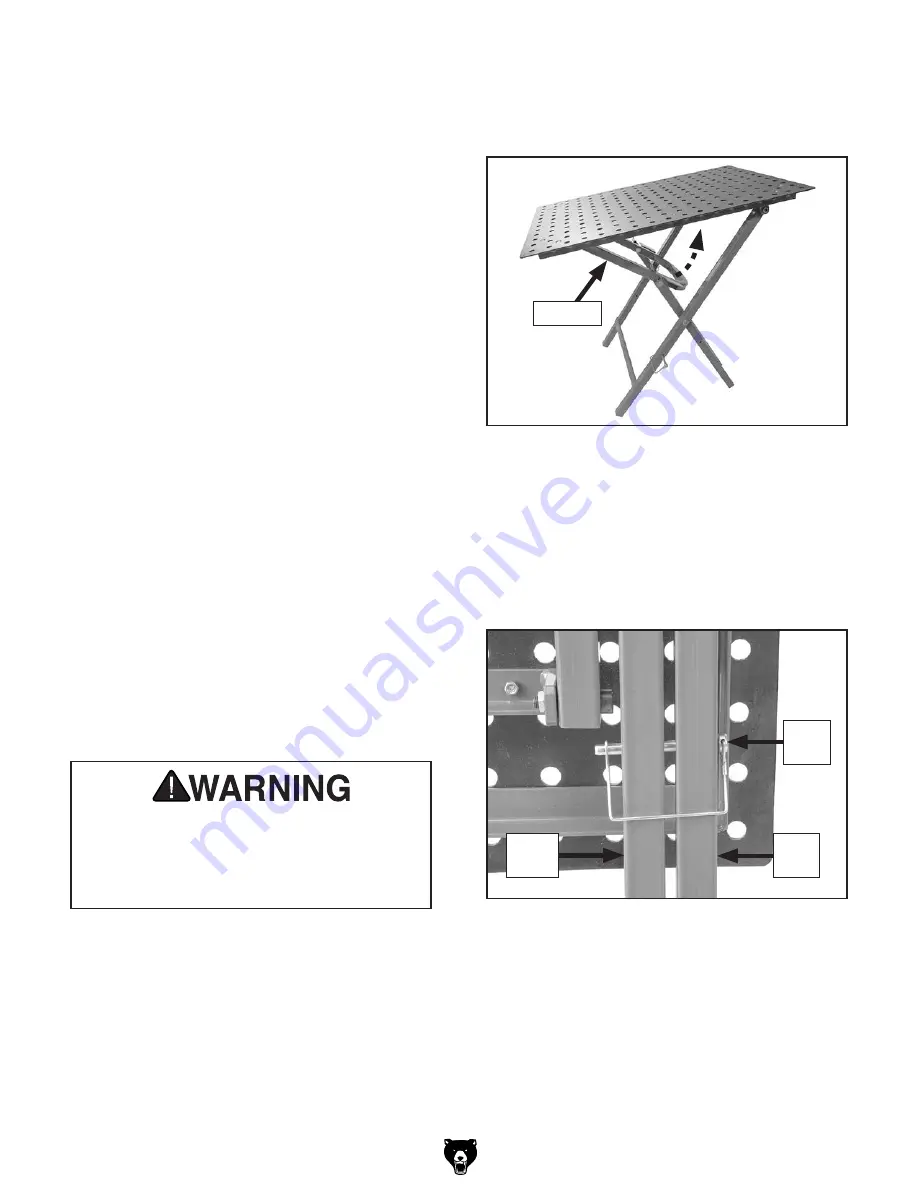

1. Lift U-brace toward underside of table, as

shown in

Figure 6.

Figure 6. Lifting U-brace to fold table.

Note:

You may need to adjust folding lock pin

(see

Figure 7) out of the way if pin prevents

folding.

2. Lean top of table against wall or work table to

secure short leg, and lock legs together with

lock pin shown in

Figure 7.

Figure 7. Long and short legs secured with lock

pin.

3. Slide into convenient location for storage.

U-Brace

Lock

Pin

Long

Leg

Short

Leg