-24-

Model T28798 (Mfd. Since 12/18)

SECTION 6: MAINTENANCE

For optimum performance from this machine, this

maintenance schedule must be strictly followed.

Ongoing

To maintain a low risk of injury and proper

machine operation, if you ever observe any of the

items below, shut down the machine immediately

and fix the problem before continuing operations:

•

Loose mounting bolts.

•

Check/empty dust collection drawer/tray.

•

Check/replace filters.

•

Worn or damaged wires.

•

Any other unsafe condition.

Monthly Check

•

Clean dust buildup from inside cabinet and

off motor. Inspect and clean inside ducts.

Every 10–15 Hours

•

Clean 30-Micron stainless steel mesh filter.

Every 25–30 Hours

•

Clean 5-Micron active carbon filter.

Every 35–40 Hours

•

Clean 1-Micron pleated micro filter.

Every 300 Hours

•

Replace 5-Micron active carbon filter and

pleated micro filter every 300 hours or sooner

if cleaning filters no longer improves airflow.

See

Page 26 for air filter cleaning instructions.

Schedule

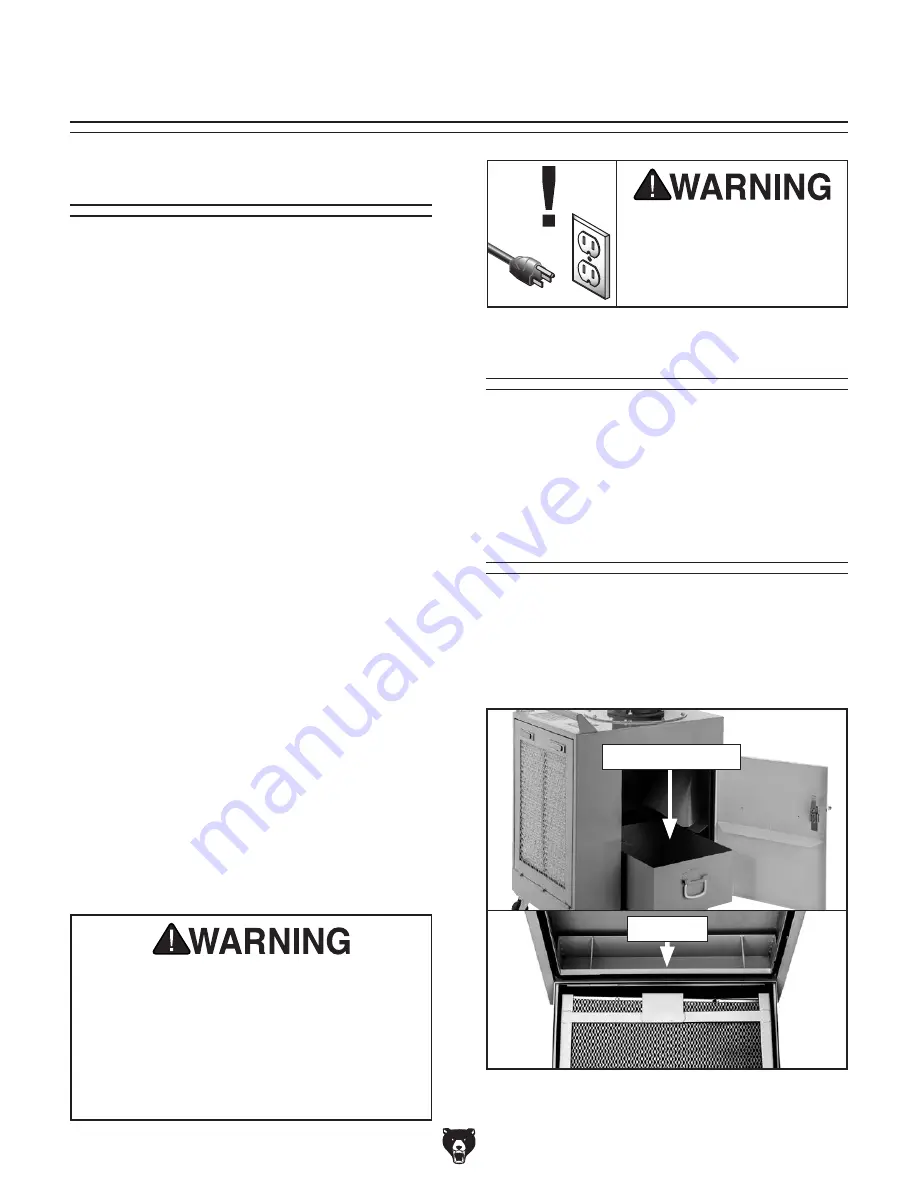

Cleaning Collection

Drawer & Dust Tray

Frequently monitor and empty collection drawer

and dust tray during operations (see

Figure 30).

Wear NIOSH-approved respirator, ANSI-approved

safety goggles, and leather gloves when inspect-

ing or emptying drawer or tray.

Cleaning Exterior

To clean the exterior of the Model T28798, wipe

off dust with a dry cloth.

To reduce risk of shock or

accidental startup, always

disconnect machine from

power before adjustments,

maintenance, or service.

Wear ANSI-approved safety goggles,

a NIOSH-approved respirator, and leath-

er gloves when removing, cleaning, and

replacing filters. Carefully minimize amount

of dust allowed to become airborne, and

prevent spread of dust onto hands or cloth-

ing. Dispose of all waste properly according

to local regulations for material type.

Figure 30. Collection drawer and

air filter dust tray.

Dust Tray

Collection Drawer

Summary of Contents for T28798

Page 15: ...Model T28798 Mfd Since 12 18 13 5mm Hardware Recognition Chart...

Page 36: ......