model t10432 (mfg. since 11/10)

-15-

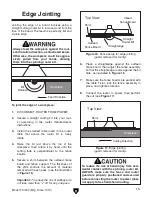

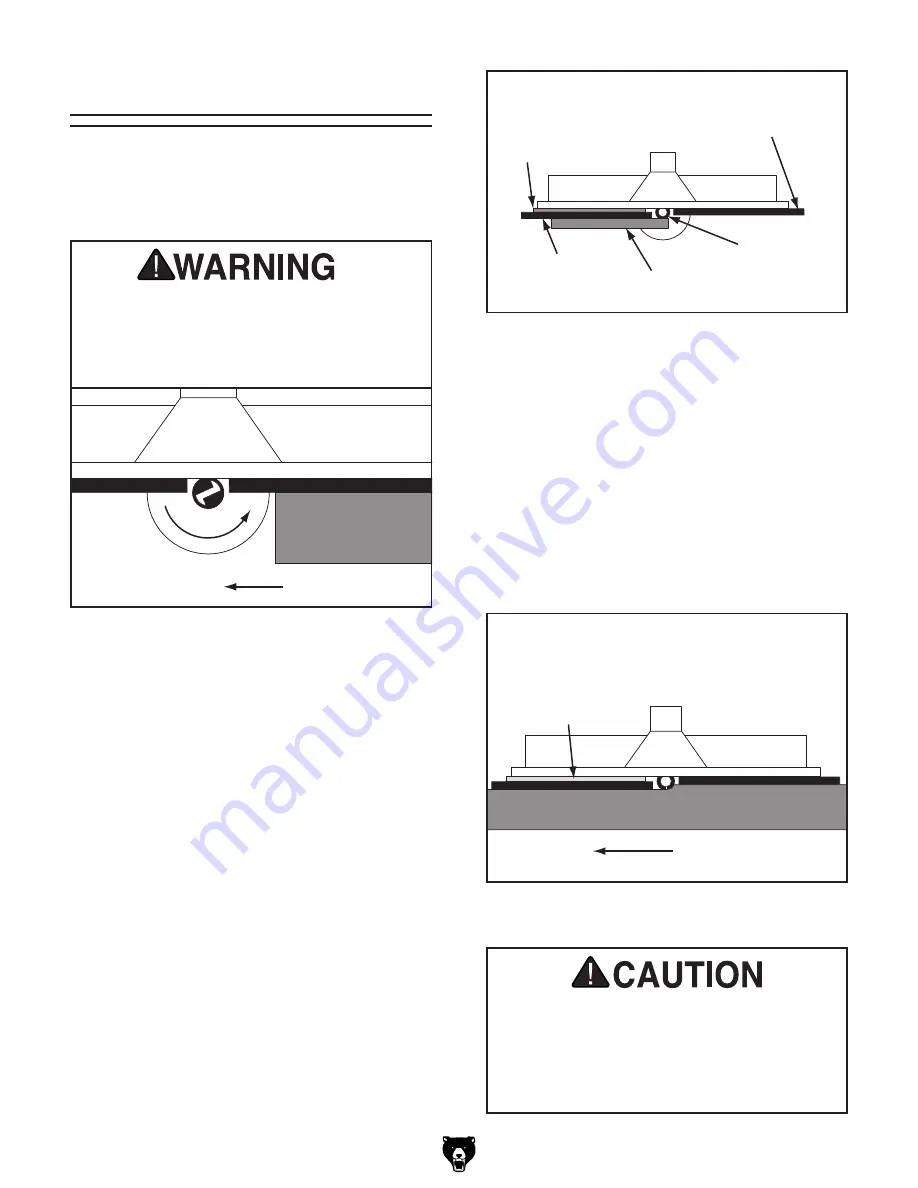

Edge Jointing

Jointing the edge of a board involves using a

straight cutting router bit to remove wood from the

face of the board. the result is a perfectly flat and

square edge.

To joint the edge of a workpiece:

1. disConneCt router From poWer!

2. secure a straight cutting bit into your rout-

er according to the router manufacturer's

instructions.

3. install the smallest table insert in the router

table that allows the router bit to freely

rotate.

4. raise the bit just above the top of the

workpiece, then rotate it by hand until the

cutting flute is perpendicular to the fence

boards.

5. secure a shim between the outfeed fence

board and fence support. the thickness of

the shim controls the amount of material

removed with each pass. (see the illustration

in

figure 16).

important:

To reduce the risk of kickback, do

not take more than

1

⁄

8

" off for any one pass.

Straightedge

Shim

Outfeed

Fence Board

Straight

Router Bit

Infeed

Fence Board

Top View

figure 16. Fence setup for edge jointing

(guard removed for clarity).

6. place a straightedge against the outfeed

fence board, then adjust the fence assembly

so that the straightedge is also against the bit

flute, as illustrated in

figure 16.

7. make sure the fence boards are parallel with

the table t-slot, lock the fence assembly in

place, and tighten all knobs.

8. Connect the router to power, then perform

the cut (see

figure 17).

Top View

Cutting Direction

Shim

Workpiece

figure 17. edge jointing

(guard removed for clarity).

Workpiece

Feed Direction

Bit

Rotation

Always feed the workpiece against the rout-

er bit rotation direction, as illustrated below.

Otherwise, the workpiece could be aggres-

sively pulled from your hands, drawing

them into the spinning router bit.

To reduce the risk of hand injury from acci-

dental contact with the spinning router bit,

ALWAyS make sure the fence and router

guard are properly positioned and secured

before connecting the router to power (does

not apply to free hand-hand routing.