Model g0634Xp (Mfg. 4/11+)

-9-

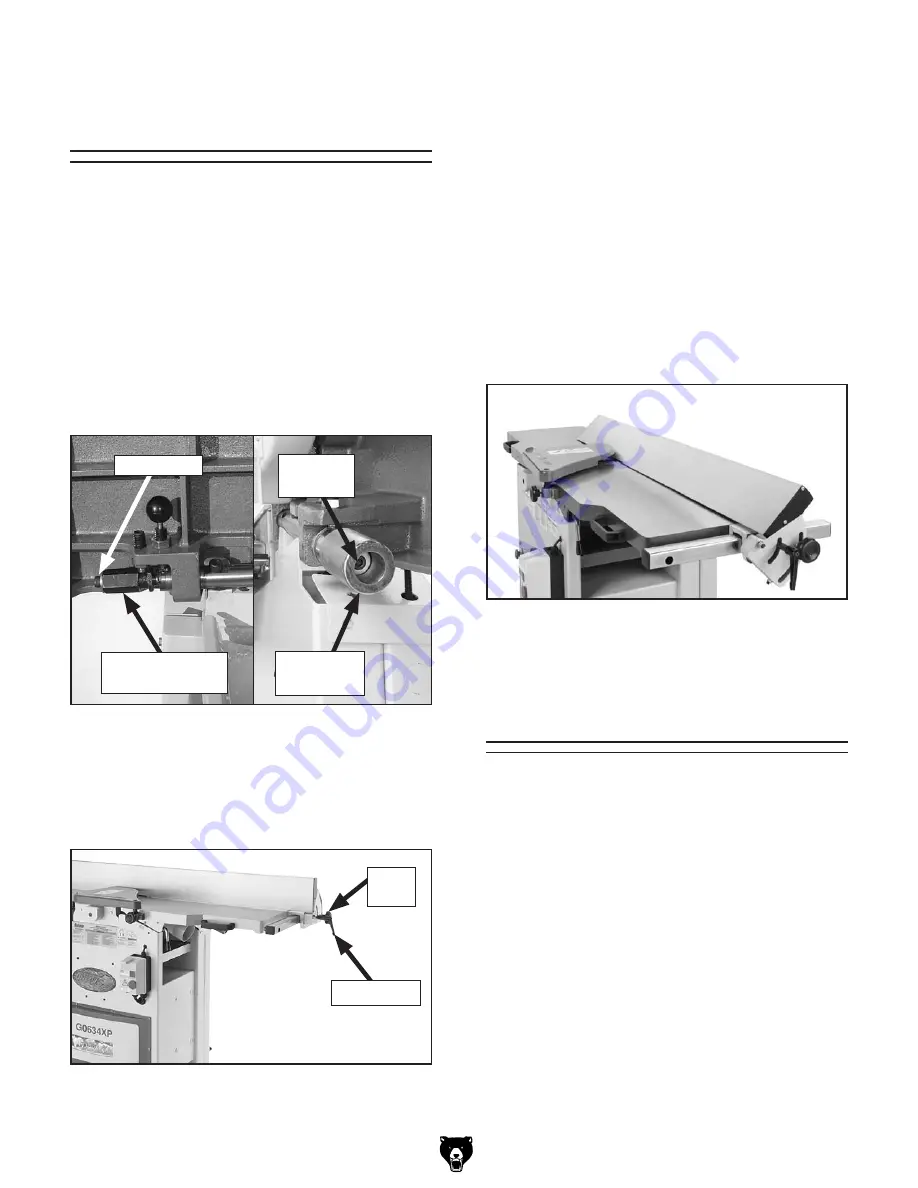

figure 6. Fence at 45° outward position.

to move the fence to 45° outward, loosen the tilt

knob, move the fence

to the 45° outward position

(see

figure 6), then tighten the tilt knob. Verify the

angle with a 45° square. to return the fence to the

90° position, loosen the tilt knob, raise the fence

to 90°, and tighten the tilt knob. Check the fence

angle with a 90° square, and make sure the fence

and table are flush.

basic Jointer

controls

All basic controls used during routine jointer oper-

ations on the g0634Xp are the same as those

described on

pages 22–23 of the manual except

for "table Movement," "Fence Movement," and

"Fence tilting."

fence tilting: the tilt knob (figure 5) secures

the fence at any position in the available range.

Fence stops set the fence at 90° or 45° outward.

the tilt knob must be tightened before jointing.

see

page 10 in this insert for more detail on

adjusting the fence stops.

fence movement: the fence lock lever keeps

the fence in position (see

figure 5). to move

the fence, loosen the lever, slide the fence in the

desired direction, then tighten the lever.

figure 5. Fence lock location.

tilt

Knob

lock lever

Jointer-planer

conversion

Model g0634Xp jointer-planer operations are the

same as those described on

pages 24–25 of the

manual, with the exception of

step 3.

to set up the machine for planer operations:

1. disCoNNECt JoiNtEr/plANEr FroM

poWEr soUrCE!

2. remove the cutterhead guard.

3. loosen the fence lock lever (figure 5) and

slide the fence off of the machine.

4. perform steps 4–9 in the manual.

table movement: Unlock the table lock levers,

then loosen the cap screws on the infeed handgrip

or outfeed table adjustment knob (see

figure 4)

before moving the infeed and outfeed tables. Use

an adjustable wrench to turn the outfeed adjust-

ment knob.

figure 4. table control locations.

outfeed table

Adj. Knob

infeed

handgrip

Cap screw

Cap

screw