H2909 18 Gauge Stapler Kit

-3

-

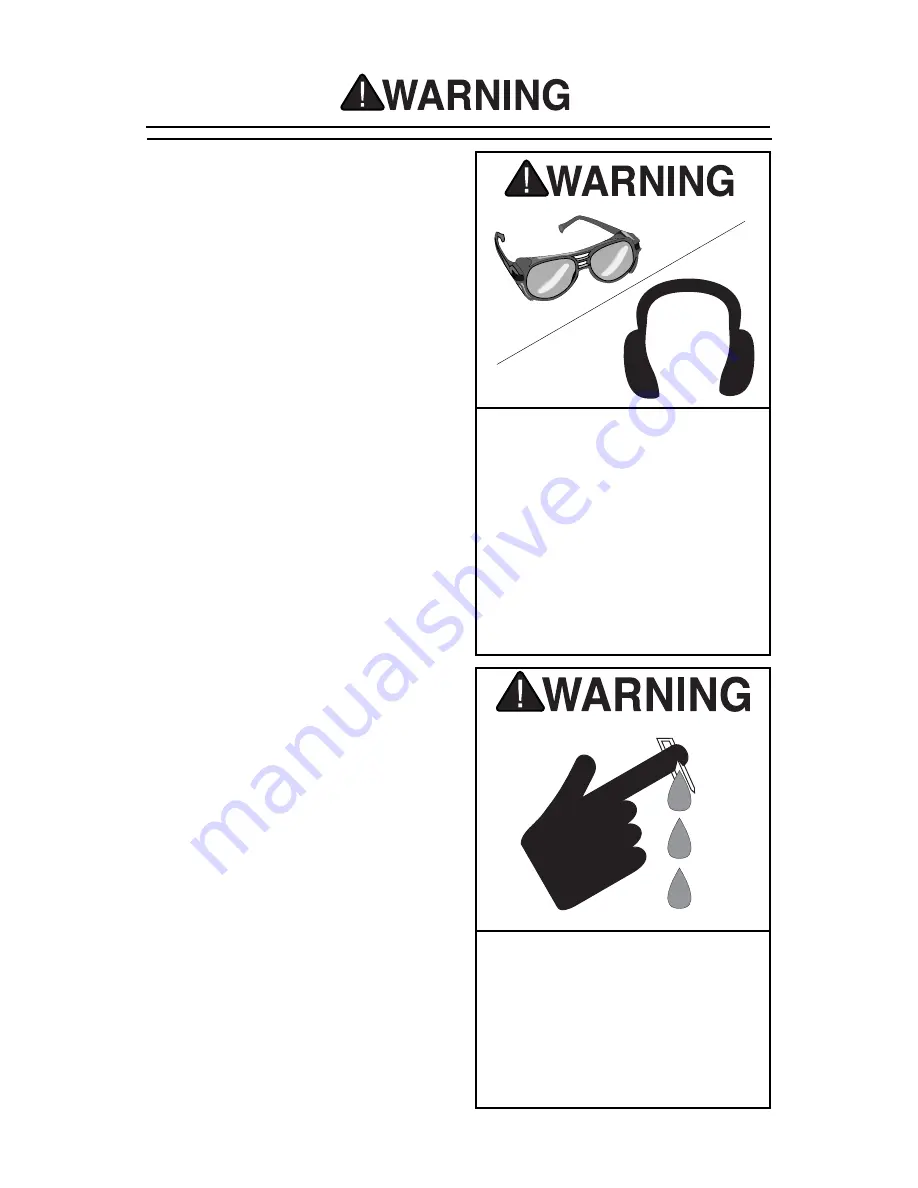

Operating this stapler can propel

objects into the air, causing immedi-

ate eye damage. To protect yourself,

always wear American National

Standards Institute (ANSI) approved

safety glasses or goggles when oper-

ating this equipment. In addition, this

stapler discharges at 85-90 decibels.

To protect your hearing, always wear

ANSI approved ear protection when

operating this stapler.

Basic Stapler Safety

In addition to the rules stated in the previ-

ous section, and those in the warning

boxes throughout this manual, please

observe the following safety tips for your

new stapler:

1.

READ THIS ENTIRE MANUAL

BEFORE OPERATING THE STA-

PLER.

2.

ALWAYS DISCONNECT AIR FROM

THE STAPLER

whenever servicing

or installing staples. During mainte-

nance, a stapler connected to air may

fire accidentally, causing serious per-

sonal injury.

3.

DO NOT PLACE HANDS NEAR

STAPLE POINT OF ENTRY.

Staple

can deflect and tear through the sur-

face of the workpiece, puncturing

your hand or fingers.

4.

NEVER CONNECT THE STAPLER

TO PRESSURIZED OXYGEN OR

OTHER COMBUSTIBLE GASES

as

a power source. Only use filtered,

lubricated, and regulated compressed

air.

5.

NEVER USE GASOLINE OR

OTHER FLAMMABLE LIQUIDS TO

CLEAN THE STAPLER.

Vapors in

the tool will ignite by a spark and

cause the tool to explode.

6.

DO NOT CARRY THE STAPLER BY

ANY OTHER PART THAN THE

HANDLE,

and do not carry the sta-

pler by the air hose.

7.

DO NOT KEEP THE TRIGGER

PULLED ON THE SAFETY YOKE

MECHANISM WHEN CARRYING

OR HOLDING THE TOOL.

8.

DO NOT USE A CHECK VALVE OR

ANY OTHER FITTING

that allows air

to remain in the tool

.

Never point this stapler at yourself or

another person! Always pay attention

to the direction this stapler is pointed.

Use this tool with respect and caution

to lessen the possibility of operator or

bystander injury. Ignoring this warn-

ing may result in serious personal

injury.