-18-

g9298/g9299/g9300 rotary table

Surface Care

nicks, dings, and scratches on the surface of the

rotary table and base can have an adverse effect

on accuracy and may damage the workpiece or

mill table.

prior to use, dress or "stoning" these surfaces

with a fine sharpening stone. A few strokes of the

stone on the table surface, the machined base

and back, and the mill table will help to ensure

longevity and accuracy. Make sure to thoroughly

wipe these surfaces clean to remove any dust

generated from the process.

preload

A precision spacer is installed under the keeper

on the back of the rotary table to maintain the

proper amount of preload. With use, the spacer

surface that the keeper rubs against may become

worn.

you can test the preload by mounting the rotary

table horizontally on the mill table, positioning the

tip of a test indicator on the surface of the rotary

table, then attempting to lift the table up from the

base. the table is properly preloaded when no

motion is measured. if motion is detected by the

test indicator, perform the procedure below to cor-

rect the amount of preload.

Tools Needed

Qty

hex Wrench 5mm .............................................. 1

Fine sharpening stone ...................................... 1

To correct the amount of preload:

1. turn the rotary table horizontally upside down

on a protected surface.

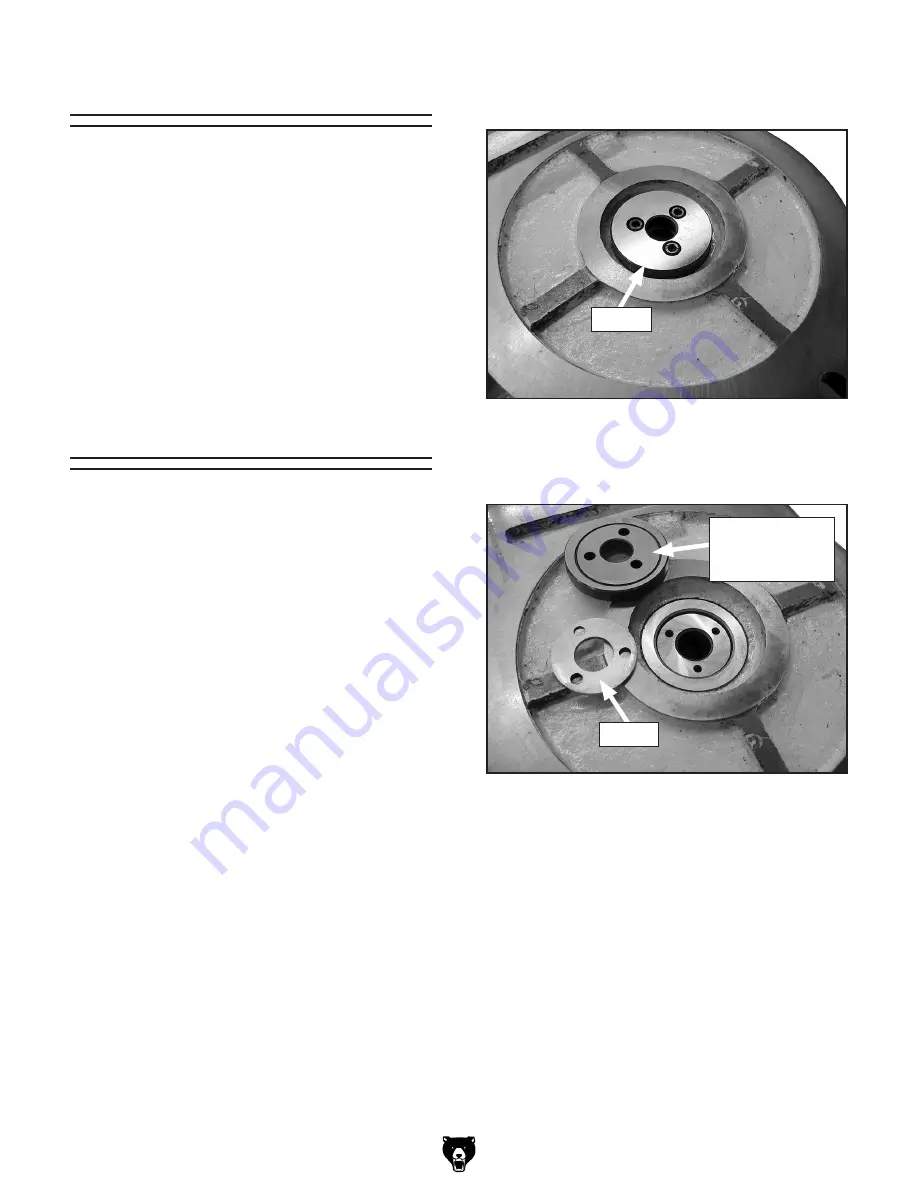

2. remove the three cap screws shown in

figure 21 that secure the keeper.

figure 21. Keeper and cap screws.

Keeper

3. remove the keeper and the spacer (see

figure 22).

figure 22. Keeper and spacer removed from the

rotary table.

spacer

Keeper

(shown upside

down)

4. stone the spacer as instructed in the previ-

ous

Surface Care subsection on this page.

5. thoroughly clean all of the mating surfaces,

then apply a thin coat of light machine oil to

all parts.

6. re-assembly the parts and test the preload

again. if necessary, repeat this procedure

until you have attained the proper amount of

preload.