-56-

Model G0948 (Mfd. Since 08/21)

1. Cut a piece of scrap wood approximately

3

⁄

4

"

thick x 3" wide x 17" long. On wide face of

board, draw a straight line parallel to long

edge.

2. Slide bandsaw fence out of way and cut

along the line halfway through the board.

Turn bandsaw

OFF and wait for blade to

stop. Do not move board.

3. Clamp board to bandsaw table, then slide

fence over to board so it barely touches one

end of board.

4. Loosen fence adjustment cap screws, skew

fence so it is parallel with scrap piece, then

tighten cap screws.

5. Make a few cuts using fence.

— If blade lead is still present, repeat

Steps 1–4 until blade and fence are paral-

lel with each other.

Blade Lead

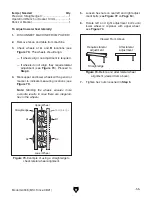

Bandsaw blades may wander off the cut line when

sawing, as shown in

Figure 75. This is called

blade lead.

Figure 75. Example of blade lead.

Item(s) Needed

Qty

Hex Wrench 4mm. ............................................. 1

Scrap Wood

3

⁄

4

" x 3" x 17" ................................. 1

Clamp 4" ............................................................ 1

1. Make sure blade is properly tensioned, and

blade guides are adjusted correctly.

2. Use less pressure when feeding workpiece

through cut.

3. Make sure miter slot and fence are parallel to

blade line (see

Aligning Table and Aligning

Fence procedures for detailed information).

4. Perform test cut with bandsaw.

— If there is still blade lead present, com-

pensate for this condition by skewing

the fence, as instructed in the following

procedures.

Correcting Blade Lead

Skewing Fence

Blade lead is usually caused by too fast of a

feed rate, a dull or abused blade, or improper

blade tension. If your blade is sharp/undamaged,

properly tensioned, and you still have blade lead,

perform the following procedures.

Summary of Contents for G0948

Page 68: ......