-32-

Model G0815 (Mfd. Since 09/18)

Lubrication

Your planer features bearings that are lubricated

and sealed at the factory. These bearing do not

require any further attention unless they need

to be replaced. If a bearing fails, your planer will

probably develop a noticeable rumble or vibration,

which will increase when the machine is under a

load. The bearings are standard sizes and can be

replaced through Grizzly.

Follow the maintenance schedule on

Page 31 and

the following procedures to properly lubricate the

other planer components, which are essential for

long life and trouble-free operation of your planer.

NOTICE

Failure to follow reasonable lubrication

practices as instructed in this manual for

your machine could lead to premature fail-

ure of components and void the warranty.

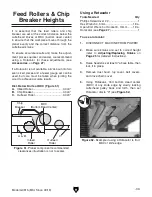

Feed Roller Bushings

Oil Type ................SB1365 or ISO 68 Equivalent

Oil Amount ...........................................2–3 Drops

Frequency ................ Every 8 Hours of Operation

The infeed and outfeed rollers rotate inside bush-

ing blocks on both ends of the rollers. Add 2–3

drops of ISO 68 machine oil to the center hole of

the four feed roller tension adjustment bolts on top

of the head casting (see

Figure 41).

Figure 41. Lubrication of feed roller bushings.

Lubricate

Here

Figure 40. Recommended products for machine

lubrication.

SB1365—South Bend Way Oil-ISO 68

T26419—Syn-O-Gen Synthetic Grease

Summary of Contents for G0815

Page 56: ......