Model G0781 (Mfd. Since 2/15)

-33-

Adjusting Gibs

The gibs affect the accuracy of the work table by

restricting slide movements along their ways.

Screws on each axis end allow gib adjustment to

increase or decrease the friction between the slid-

ing surfaces of the ways.

The goal of gib adjustment is to remove unneces-

sary sloppiness without causing the X-, Y- and

Z-axis ways to bind. Tight gibs make the move-

ments more accurate, but harder to perform.

Loose gibs make the movements sloppy, but

easier to perform.

Tip: Many experienced machinists adjust the gibs

until there is just a slight drag in table movement.

Tools Needed:

Qty

Hex Wrench 3mm .............................................. 1

Wrench 10mm ................................................... 1

To adjust gibs:

1. DISCONNECT MACHINE FROM POWER!

2. Make sure desired X-, Y- and Z-axis lock lever

is loose.

3. Loosen hex nuts on gib screws along desired

gib adjustment (see

Figure 38).

4. Loosen set screws and move sliding device

back-and-forth to make sure gibs are loose,

then tighten set screws until you feel light

resistance in the handwheel.

5. Use hex wrench to prevent set screws from

moving, then re-tighten hex nuts to secure

the setting.

6. Re-check movement of slide and, if neces-

sary, repeat

Steps 3–5.

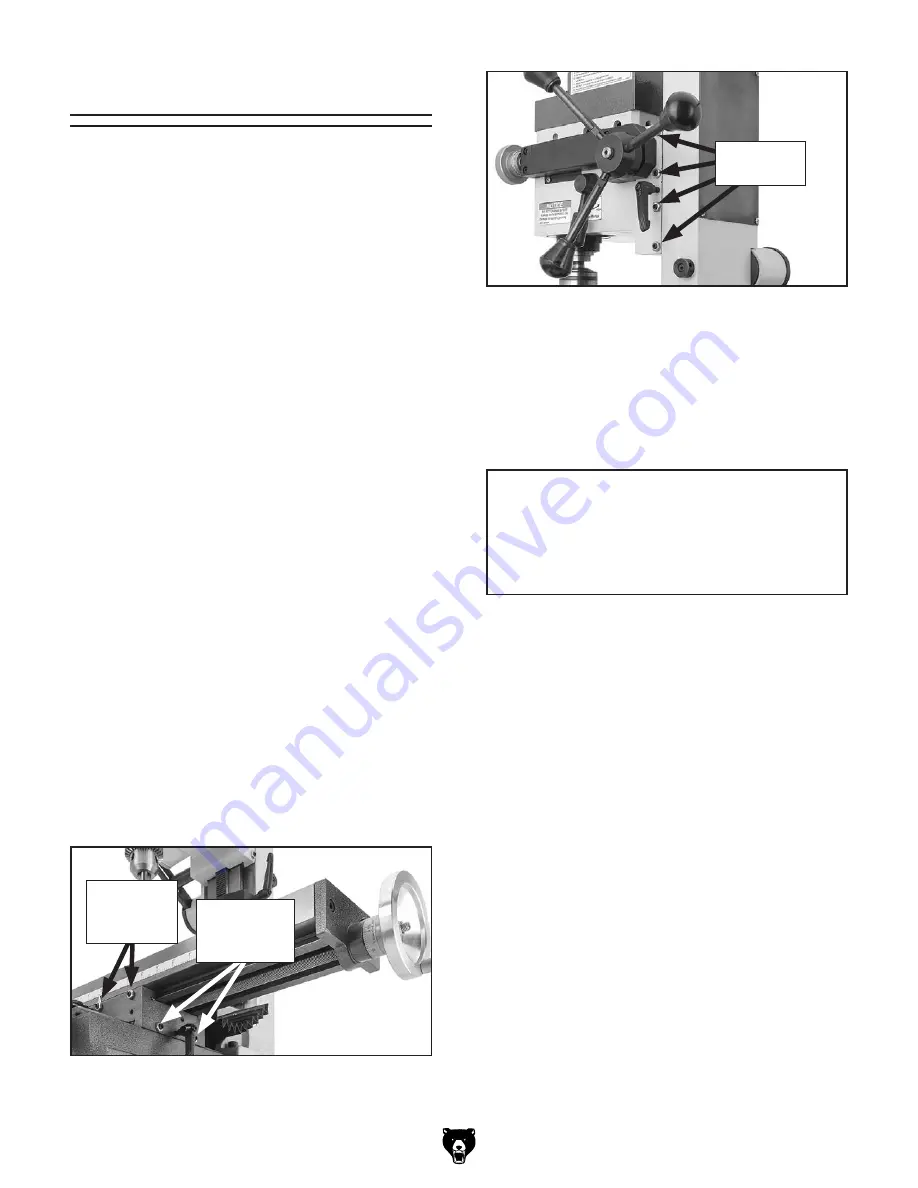

Figure 39. Location of Z-Axis gib screws.

Z-Axis Gib

Screws

NOTICE

Excessively loose gibs may cause poor

workpiece finishes. Excessively tight gibs

may cause premature wear of sliding sur-

faces and ways.

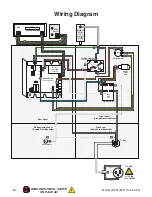

Figure 38. Location of gib adjustment set

screws.

Y-Axis Set

Screws

(2 of 3)

X-Axis Set

Screws and

Hex Nuts

Summary of Contents for G0781

Page 52: ......