Model g0716 (Mfg. since 2/11)

-33-

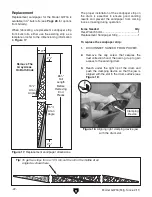

conveyor belt

tension & tracking

the conveyor belt tension and tracking must be

properly adjusted to ensure that the workpiece

correctly and safely passes underneath the sand-

ing drum and that the conveyor belt does not

become damaged during operation.

if the conveyor belt slips on the rollers then the

belt tension needs to be increased.

if the conveyor belt moves to one side or the other

when it is running, then the belt tracking needs to

be adjusted.

tools Needed

Qty

phillips screwdriver #2 ...................................... 1

open-End Wrench 10mm .................................. 1

belt tension

1. disCoNNECt saNdEr FroM poWEr!

2. Make sure the conveyor belt is centered on

the rollers.

— if it is not, release the belt tension equally

on both sides of the belt. this is done by

holding the hex nut still (see

figure 30)

while rotating the phillips head screw coun-

terclockwise until you can move the belt

from side-to-side with your hand. then,

center the belt on the rollers.

3. as a starting point, make sure that the ends

of both tensioning screws extend evenly

approximately

1

⁄

4

" beyond the hex nut, as

shown in

figure 31.

— if the belt slips during operation, rotate the

screws clockwise in small amounts until

the belt no longer slips on the rollers.

figure 317. tensioning screw extending

approximately

1

⁄

4

" beyond hex nut.

screw Extends

approximately

1

⁄

4

"

belt tracking

1. run the conveyor belt at high speed and note

if it tracks to one side or the other—this make

take a couple of minutes to show up.

Note:

To avoid damaging the belt, do not

allow the belt to track off the rollers.

— if the conveyor belt does not track to one

side or the other, no further adjustments

are necessary.

Note:

In the next step, you may have to wait

for several minutes to notice a change in

tracking.

2. rotate the tensioner screw clockwise on the

side the belt is tracking toward until the belt

moves to the center of the rollers, then back

off the screw until it stops tracking to the

opposite side.

3. allow the belt to run for several minutes to

make sure it is tracking properly. if neces-

sary, repeat this procedure until the belt is

properly tracking.

figure 30. Conveyor belt tensioners.

hex Nut

tensioners

screw