6

7. Operating & Maintenance Instructions

Prior to tool operation

The tool is intended to be operated as a hand held tool. It is always recommended

that while using the tool, operators stand on a solid floor, in a secure position with a

firm grip and footing. Be aware that the tool can develop a torque reaction. See the

section “SAFETY PRECAUTIONS.”

Please Note:

Use a clean lubricated air supply that will give a measured air

pressure at the tool of 6.2 bar (90 psig) when the tool is running with the lever fully

depressed. It is recommended to use an approved 10 mm (3/8 in) x 15.24m (50

ft) maximum length air line.

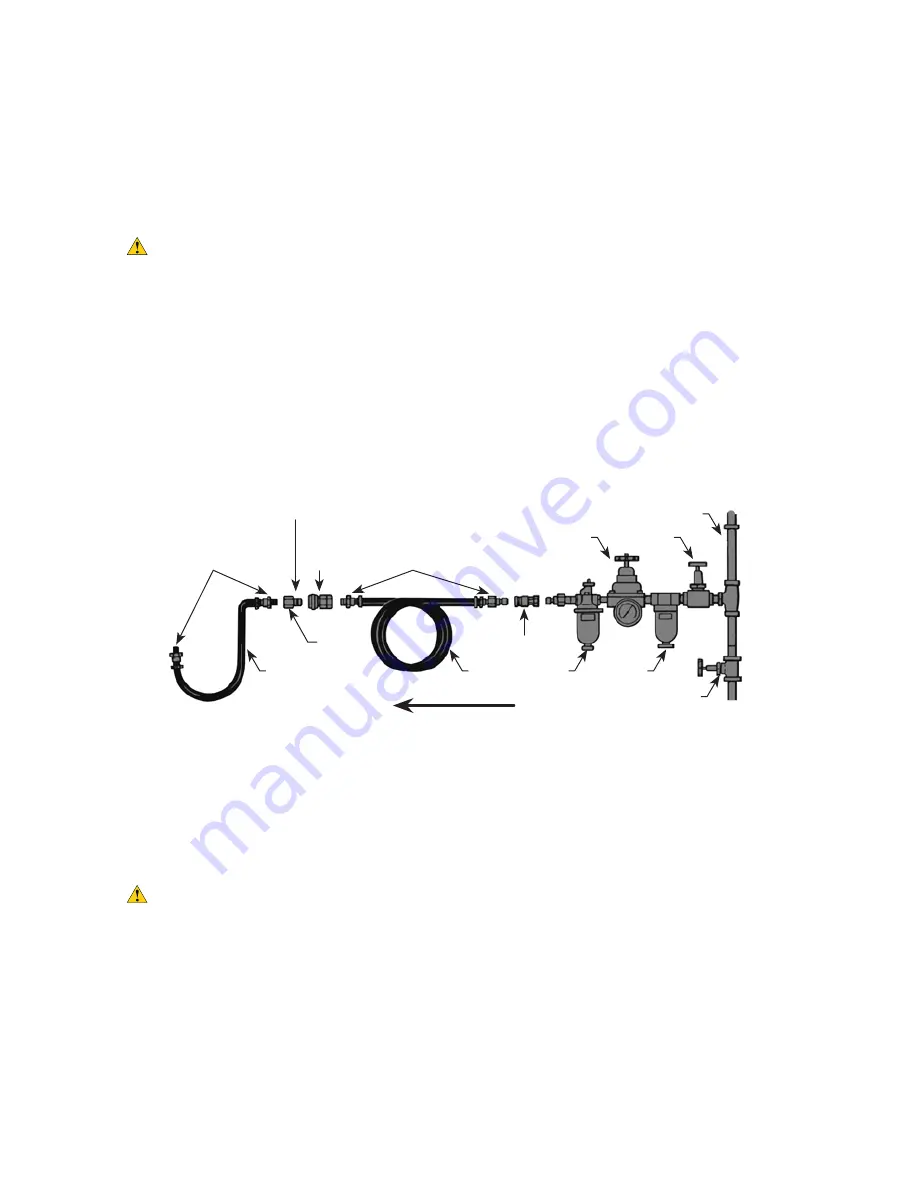

Connect the tool to the air supply as shown in Figure 1. Do not connect the tool

to the air line system without an easily accessible air shut off valve. It is strongly

recommended that an air filter, regulator, and lubricator (FRL) be used as shown in

Figure 1 as this will supply clean, lubricated air at the correct pressure to the tool.

In any case where the supply pressure exceeds the marked maximum of the tool,

appropriate air pressure regulators should be used while operating this tool.

It is recommended that the air pressure at the tool be 6.2 bar (90 psig) while the

tool is running so the maximum RPM is not exceeded. The tool can be run at lower

pressures but should never be run higher than 6.2 bar (90 psig). If run at lower

pressure the performance of the tool is reduced.

Maintenance

Caution:

Always disconnect tool from air supply prior to maintenance.

a) Before using Griot’s Garage THE BOSS

™

AIR Micro Rotary Polisher, it is

recommended to add four to five drops of air tool oil into the air inlet opening

and 1 - 2 drops following every 3 - 4 hours of use.

b) Clean plastic and rubber parts with a soft, damp cloth. NEVER use solvents to

clean plastic parts. Griot’s Garage Interior Cleaner is an effective solution.

c) Check for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents are caused by poorly maintained

power tools.

Tailpiece Adapter

Oil Here Daily

Coupling Tailpiece Adapter

Regulator

Stop Valve

Pipes & Fittings

Filter

Oiler

Coupling

Main Hose

Adapter

Whip Hose

Air Supply

Drain Daily