Wiring

• Deactivate the 24 Vac/dc power supply until all connections are made to the device to prevent electrical shock or equipment

damage.

• Use 14-22 AWG shielded wiring for all connections and do not locate the device wires in the same conduit with wiring used

to supply inductive loads such as motors. Make all connections in accordance with national and local codes.

• Pull at least six inches of wire into the enclosure, then complete the wiring connection according to the wire diagram for the

applicable power supply and output signal type.

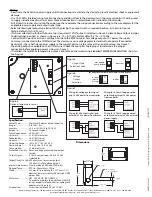

• Select desired signal output type (mA or Vdc) by placing the output switch in required position, as shown in Figure 5.

Factory default is mA (4-20 mA).

• If mA was selected, no further Output set up is required. If VOLT output is selected in Figure 5, place Voltage Output Jumper

to desired span position, as shown in Figure 6. ie: 10 = 0-10 Vdc. Factory default is 10v = 0-10Vdc.

• Connect the DC positive or the AC voltage hot side to the PWR terminal. For voltage output or AC power, the supply

Common is connected to the COM terminal. The device is reverse voltage protected and will not operate if connected

backwards. It has a half-wave power supply so the supply Common is the same as the signal Common. See Figure 7.

•The analog output is available on the OUT terminal. Check the controller Analog Input to determine the proper

connection before applying power as shown in Figure 7.

• If installed, the resistance temperature output is available on the two terminals labelled TEMPERATURE SENSORas shown in

See Figure 8.

Voltage

Output

Selection

0-10 Vdc

(Factory

default)

mA = 4-20 mA

(Factory Default)

Output Type

Selection Switch

Figure 6

Figure 5

Figure 8

Dimensions:

PRINTED IN C

ANAD

A

V. RH200A 10/14

Figure 7

Wiring for voltage output signal

and 24 Vdc power from controller

Wiring for all output signals and

external 24 Vac power transformer

24 Vdc Power Supply

0-5 Vdc

VOLT = Vdc

* No setting required if output selection switch is set to mA in Figure 5

Specification:

Sensor Type:...................Thermoset Polymer based Capactive

Range:..............................0 to 100% RH

Accuracy:........................±2, 3, or 5% RH (5 to 95% RH)

Response:.......................15 Seconds typical

Temp Dependence:....±0.05% RH/ ˚C

Hysteresis:......................±1.5% RH maximum

Repeatability:...............±0.5% RH typical

Linearity:........................±0.5% RH typical

Operating Range:........-40 to 85˚C (-40 to 185˚F)

Power Supply:...............18 to 30 Vdc, 15 to 26 Vac

Consumption:...............22 mA maximum

Protection Circuitry:...Reverse voltage protected and output

limited

Output Signal:..............4-20 mA current loop, 0-5 or 0-10 Vdc

(selectable)

Output Drive @ 24 Vdc:..550 ohms max for current output

10K ohms min for voltage output

Internal Adjustments:.Clearly marked ZERO and SPAN pots

Optional Temp.:............RTD’s or Thermistors. 2 Wire

Probe:..............................230 mm (9”) probe length x 12.7 mm (1/2”)

diameter stainless steel with 60 micron HDPE

porous filter

Enclosure:......................ABS - UL94-5VB - IP61 (NEMA 2)

*In order to maintain the published NEMA/IP

ratings, properly rated conduit or cable gland

adapters must be used.

Termination:.................Screw terminal block (14 to 22 AWG)

84.3 mm

3.320 “

115.8 mm

4.56 “

53.6 mm

2.110 “

228.60 mm

9”

2X Ø 0.850”

12.70 mm

0.50“

304 Series S/S Probe

60 micron HDPE filter

Wiring for 4-20 mA loop-powered

output and external 24 Vdc external

power supply

Wiring for 4-20 mA loop-powered

output and external 24 Vdc power

from controller

Optional Temperature Sensor

Greystone Energy Systems, Inc. 150 English Drive, Moncton, NB E1E 4G7 Canada Tel: +1-506-853-3057 Tollfree (North America): +1-800-561-5611 Fax: +1-506-853-6014

Email: [email protected] Web: www.greystoneenergy.com

Cop

yr

igh

t © Gr

ey

stone Ener

gy S

yst

ems I

nc

. A

ll R

igh

ts R

eser

ved