15

Laboratory Exhaust Systems

®

Recommended Bearing Lubrication Schedule

Relubrication Schedule in Months*

Synthetic Grease

Fan

RPM

Bearing Bore (inches)

1

⁄

2

-

1

1

1

⁄

8

-

1

1

⁄

2

1

5

⁄

8

-

1

7

⁄

8

1

15

⁄

16

-

2

3

⁄

16

2

7

⁄

16

- 3

3

3

⁄

16

-

3

1

⁄

2

3

15

⁄

16

-

4

1

⁄

2

4

15

⁄

16

-

5

1

⁄

2

To 250

12

12

12

12

12

12

12

12

500

12

12

12

12

12

12

12

12

750

12

12

12

12

12

12

10

7

1000

12

12

12

12

12

9

6

4

1250

12

12

12

12

9

6

4

2

1500

12

12

12

10

7

4

2

2000

12

10

8

6

3

1.5

.5

2500

12

7

5

4

1

.5

3000

12

5

3

2

.5

3500

12

3

2

.75

4000

12

2

.5

5000

12

1

Number

of shots**

4

8

8

10

16

25

41

57

* Lubrication interval is based on 12 hour day operation and

maximum 160°F housing temperature. For 24 hour per day

operation, the interval should be cut in half.

** Lubricant should be added with the shaft rotating and

until clean grease is seen purging from the bearing. The

lubrication interval may be modified based on the condition

of the purged grease. If bearing is not visible to observe

purged grease, lubricate with number of shots indicated for

bore size.

• For conditions including high temperatures, moisture, dirt

or excessive vibration, consult the factory for a specific

lubrication interval for your application.

• Lubricant should be a high quality lithium complex synthetic

grease conforming to NLGI Grade 2. Factory recommends

synthetic Mobilith SHC100.

• The use of non-synthetic lubricants will decrease lubrication

intervals by approximately three times.

• Storage periods of three months or longer require monthly

rotation of the shaft and purging grease prior to storage and

start-up.

Vektor-MS Nozzle Bearings

The bearings for the Vektor-MS nozzle assembly are

permanently lubricated and do not require additional

grease.

Motors

Motor maintenance is generally limited to cleaning

and lubrication. Cleaning should be limited to exterior

surfaces only. Removing dust and grease buildup on

the motor housing assists proper motor cooling. Never

wash-down motor with high pressure spray.

Greasing of motors is only intended when fittings are

provided. Motors supplied with grease fittings should

be greased in accordance with the manufacturer’s

recommendations. When motor temperature does not

exceed 104ºF (40ºC), the grease should be replaced

after 2000 hours of running time.

Fans have extended grease lines to lubricate the motor

without removal of any guarding.

Bearings (Arrangement 9)

The bearings for Vektor fans are carefully selected to

match the operating conditions of the specific class,

arrangement, and fan size. The instructions provided

in this manual and those provided by the bearing

manufacturer will minimize any bearing problems.

Bearings are the most critical moving part of the fan,

therefore, special care is required when mounting them

on the unit and maintaining them.

Refer to the following chart and the manufacturer’s

instructions for grease types and intervals for various

operating conditions. Never mix greases made with

different bases. This will cause a breakdown of the

grease and possible failure of the bearing.

Failure to follow recommendations may result in

premature bearing failure and is not covered under

warranty.

Do not install new belts on worn sheaves. If the sheaves

have grooves worn in them, they must be replaced

before new belts are installed.

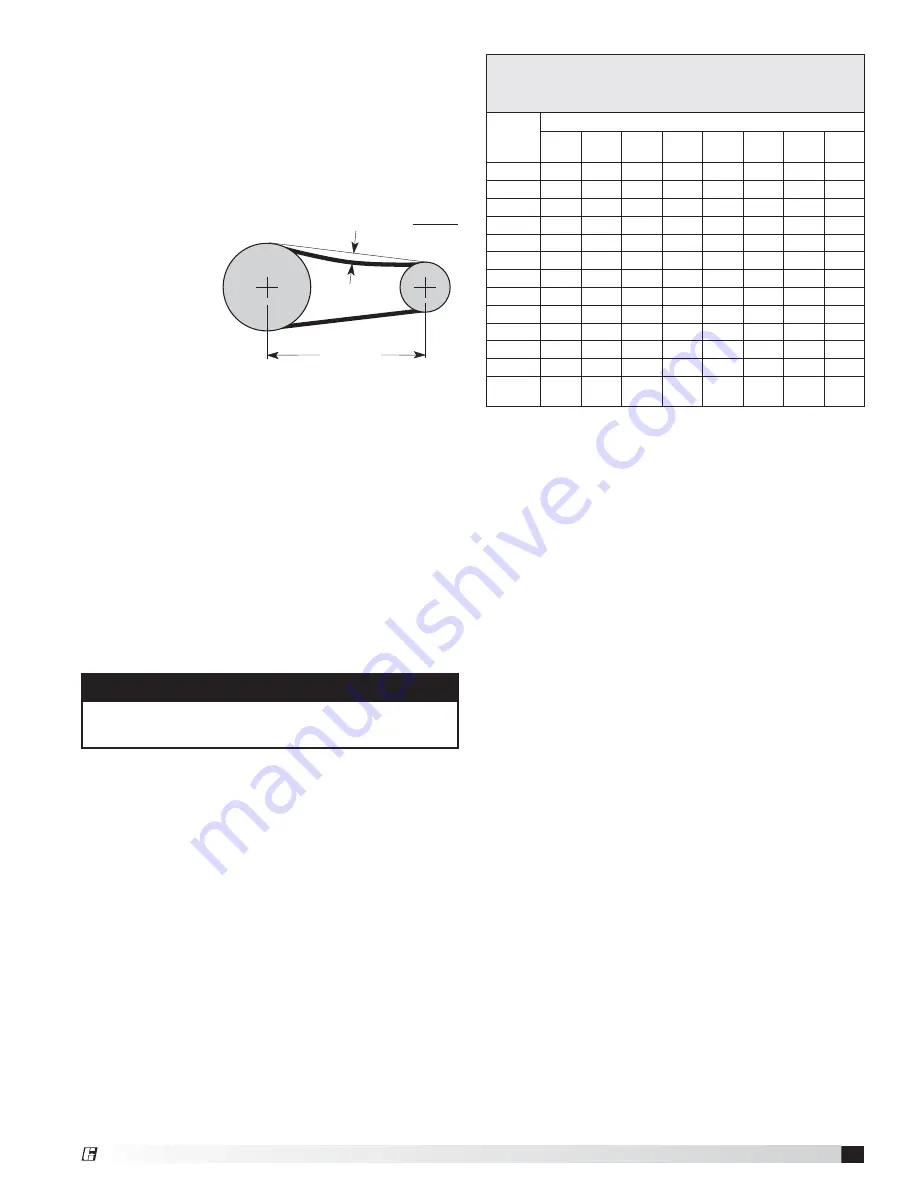

The proper tension for operating a V-belt drive is the

lowest tension at which the belts will not slip at peak

load conditions. Belts are adjusted by swinging out the

motor pivot plate. For initial tensioning, the proper belt

deflection halfway between sheave centers is 1/64 inch

for each inch of belt

span. For example,

if the belt span is

64 inches, the belt

deflection should

be 1 inch using

moderate thumb

pressure at mid-

point of the drive.

Check belt

tension two times during the first 24 hours of

operation and periodically thereafter.

Belt Span

Deflection =

Belt Span

64

NOTE

Motors for direct drive arrangement 4 models have

12 month lubrication intervals.