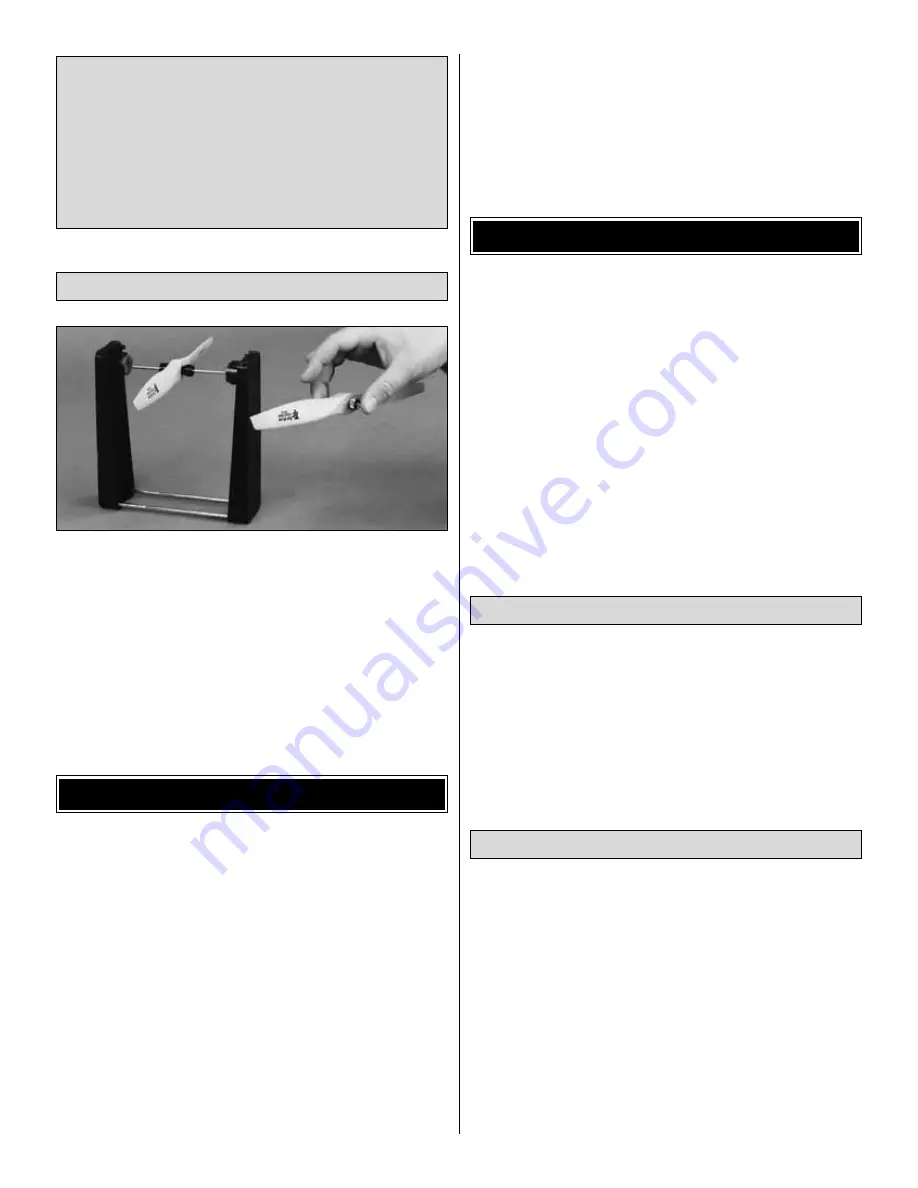

Carefully balance your propeller and spare propellers before

you fly. An unbalanced prop can be the single most

significant cause of vibration that can damage your model.

Not only will motor mounting screws and bolts loosen,

possibly with disastrous effect, but vibration may also

damage your radio receiver and battery.

We use a Top Flite Precision Magnetic Prop Balancer

™

[TOPQ5700] in the workshop and keep a Great Planes

Fingertip Prop Balancer [GPMQ5000] in our flight box.

1. The included motor will benefit from a short “break-in” by

running the motor at full throttle without the propeller for at

least 15 minutes. It is best to run the motor in 5 minute

intervals, allowing the motor to cool between runs. This will

seat the motor brushes on the commutator, insuring that the

motor will provide full power for your first flight and extend

the life of your motor. If you notice a decrease in motor

power after several flights, it may be due to carbon build-up

on the brushes or commutator. To remove this build-up,

repeat the above break-in procedure.

2. The bronze bushings in the motors are self lubricating, but

their life may be extended by applying a very small amount

of light machine oil to the point where the motor shaft

contacts the bushings after every hour or two of run time.

Note: A drop of oil is far too much. You should apply the oil

with a toothpick. Never oil the inside of the motor.

3. Using multiple battery packs to run the motor for

successive flights may cause the motor to become

excessively hot. We recommend at least a 10-minute motor

cool-down period between flights.

1. A new battery pack should be “cycled” for best results. You

should peak charge the battery, then discharge it almost

completely by actually running your motor with the propeller

attached until the auto cut-off stops the motor. To help cool

the battery, remove the battery from the plane. Do this 2 or

3 times on the ground before actually flying. Be sure you

remove the battery from the airplane between each cycle

and allow it and the motor to cool before recharging.

2. Examine your propeller for irregularities caused by the

injection molding process. Carefully remove the imperfections

with fine sandpaper.

After you break-in the motor on the model, inspect the

model closely to make sure all screws remained tight, the

hinges are secure, the prop is secure and all pushrods and

connectors are secure.

Ground check the operational range of your radio before the

first flight of the day. With the transmitter antenna collapsed

and the receiver and transmitter on, you should be able to

walk at least 100 feet [30m] away from the model and still

have control. Have an assistant stand by your model and,

while you work the controls, tell you what the control surfaces

are doing. Repeat this test with the motor running at

various speeds with an assistant holding the model, using

hand signals to show you what is happening. If the control

surfaces do not respond correctly, do not fly! Find and

correct the problem first. Look for loose servo connections or

broken wires, corroded wires on old servo connectors, poor

solder joints in your battery pack or a defective cell, or a

damaged receiver crystal from a previous crash.

Range Check

Ground Check

PERFORMANCE TIPS

PROPER CARE OF YOUR MOTOR

Balance Propellers

CAUTION: Unless the instructions that came with your

radio system state differently, the initial charge on new

transmitter and receiver batteries should be done for 15

hours using the slow-charger that came with the radio

system. This will “condition” the batteries so that the next

charge may be done using the fast-charger of your choice.

If the initial charge is done with a fast-charger the

batteries may not reach their full capacity and you may be

flying with batteries that are only partially charged.

19