Section 2: Operating Instructions

NTS2507, NTS2509, & NTS2511 s/n+ 2019+ NTS Seeder 313-900M

7/1/19

31

Operating the Seeder

DANGER

!

To avoid serious injury or death:

•

All guards and shields must be installed and in good

•

Do not use front spike rollers, rear roller, or tires as a step.

They can move suddenly causing a falling hazard against

metal protruding objects even when they appear to be solid

against the ground.

WARNING

!

To avoid serious injury or death:

•

Always be aware of your footing and surroundings when

working on or around the seeder. Be especially careful while

standing on the walkway. Something as simple as a misstep

can cause a person to fall and become seriously injured.

•

Perform scheduled maintenance. Check for loose

•

Never carry riders on the implement or tractor. Riders can

•

Do not use implement to lift objects; to pull objects such as

fence posts, stumps, etc; or to push objects. The unit is not

designed or guarded for these uses.

•

Never make contact with underground utilities such as

1.

Contact your local utility services to mark the location

of any under ground utility services in the area.

Thoroughly inspect the work area yourself for buried

pipelines, sprinkler heads, and any unforeseen

objects underground. Mark any potential hazards.

2.

Clear area to be seeded of rocks, branches, and

other foreign objects on top the ground. Mark any

potential hazards.

IMPORTANT:

Never make turns with any of the

rollers in contact with the ground. Always lift unit up

off the ground when making turns.

IMPORTANT:

Attach seeder to a tractor before

calibrating it for proper seed dispersal rate.

3.

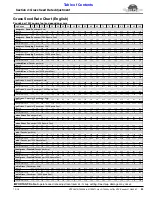

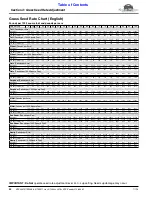

Calibrate your seeder sprocket speed and seed cup

rate adjustment lever based on type of seed you are

using. Calibration information is located on the inside

of the seedbox lid and in the

“Seed Rate Charts”

provided in this manual.

4.

Make sure each seed cup door handle is set at the

same height across the seeder. The highest position

is usually used for grass seedbox only.

5.

Be sure all bolts and nuts are tight.

6.

Be certain all guards are in place and secure.

7.

Tall grass and weeds should be mowed before

seeding.

8.

Never allow anyone to ride on the seeder.

9.

Adjust front rollers to desired angle. Make some

practice runs with main drive sprocket locked out to

determine the best roller angle for your application.

10. Lock out all-seeds drive sprocket if more than one

pass is required to prepare a seed bed before

seeding.

11. Re-engage main drive sprocket when ready to seed.

12. Do not make turns while seeder is on the ground.

13. Seeding should not be done in wet conditions as soil

will stick to the rollers.

14.

Tow Package Only:

Make sure hydraulic hoses are

attached to the tractor duplex outlet with factory float.

Lower seeder down using factory float and keep

tractor hydraulic control lever in factory float while

seeding seeds.

15.

Three Point Hook-up:

Lower seeder down until

resting on its rollers.

16. At first begin seeding at a slow forward speed and

increase speed until desired speed is achieved.

Maximum speed will vary according to soil

conditions.

17. After seeding the first 10 or 15 feet, stop and check to

see that the seeder is adjusted properly.

IMPORTANT:

Attach hydraulic hoses only to tractor

hydraulics with float capabilities.

Tractor hydraulics

for the seeder must be locked into float position

while lowering the seeder and while seeding or

the seeder can be damaged.