7

308854

Grounding

Grounding

WARNING

Improper installation or alteration of the grounding

plug will result in a risk of electric shock, fire or

explosion that could cause serious injury or death.

1.

Models 232160 through 233163, 232171 require a

120 Vac, 60 Hz, 10A circuit with a grounding

receptacle. Models 232164, 232173 requires a 230

Vac, 50 Hz, 10A circuit with a grounding recep-

tacle. Model 232166 requires a 100 Vac, 50 Hz,

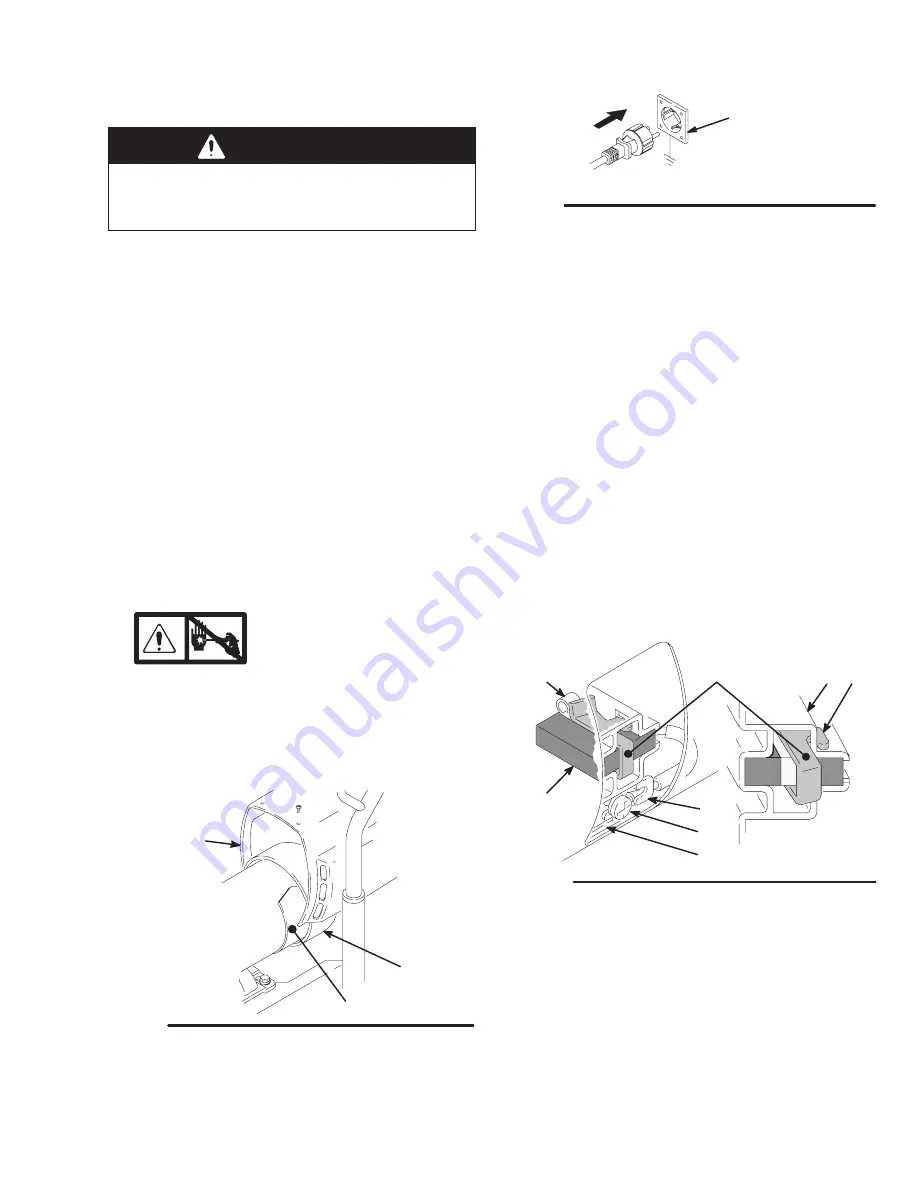

15A circuit with a grounding receptacle. See Fig. 2.

Fig. 2

Grounded

Outlet

Model 232164

9286A

2.

Do not alter ground prong or use adapter.

3.

A 1.5 mm

2

by 90 m extension cord may be used

with this equipment.

Motor Brush Replacement

NOTE:

Replace brushes worn to less than 1/2 in.

Brushes wear differently on each side of mo-

tor, check both sides. Brush Repair Kit 222157

is available for Models 232164, 232173 and

Brush Repair Kit 220853 is available for Mod-

els 232160 through 232163, 232166, 232171.

Spring clip, 110816, may be purchased sepa-

rately.

Motor Brush Removal

1.

Read

General Repair Information

; page 4.

2.

Relieve pressure

;

page 4.

3.

Fig. 3. Remove motor shield (14). Remove in-

spection covers (B) and gaskets on each side of

motor.

(Continued on page 8)

A

B

14

Fig. 3

7703B

4.

Fig. 4. Push in 110816 spring clip (A) to release

hooks (B) from brush holder (C). Pull out spring

clip.

5.

Fig. 4. Loosen terminal screw (D). Pull brush lead

(E) away, leaving motor lead (F) in place. Remove

brush (G) and spring (H).

Fig. 4

H

E

D

F

G

A

01227

B

C

6.

Inspect commutator for excessive pitting, burning

or gouging. A black color on commutator is normal.

Have commutator resurfaced by a qualified motor

repair shop if brushes wear too fast.