Capacitor Replacement

309586R

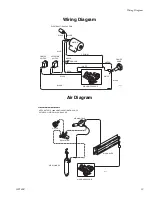

11

Capacitor Replacement

Use Capacitor Replacement Kit 246683.

Disassembly

1.

Relieve Pressure

, page 5.

2.

Unplug sprayer.

3.

Remove shroud,

(6 bolts).

4.

Capacitors can

hold a charge. To pre-

vent electric shock,

use a flat bladed

screw driver as a con-

ductive device to short

out the terminals. To

do this, touch the

blade of the flat screw

driver between two

terminal posts on the

capacitor.

5.

Cut strap.

6.

Unplug capaci-

tor and

remove.

7.

Clean surface to remove dirt and any remaining

adhesive.

Reassembly

1.

Remove backing from one side of two-sided tape

provided in kit and apply to bottom of capacitor.

2.

Plug in new capaci-

tor.

3.

Remove backing from bot-

tom of two sided tape.

Attach capacitor to plate,

pressing taped side firmly

into position. Secure using

a wire tie.

4.

Replace shroud. Tighten

bolts (6).

WARNING

page 2

CAUTION

Do not touch metal part of screw driver when

shorting out capacitor.

1

2

3

4

ti3025a

ti3166a

Wires are not polarized. It does not matter which

wires are connected together between capacitor

and motor.

ti3167a

ti3168a

ti3090a