Maintenance

24

309297K

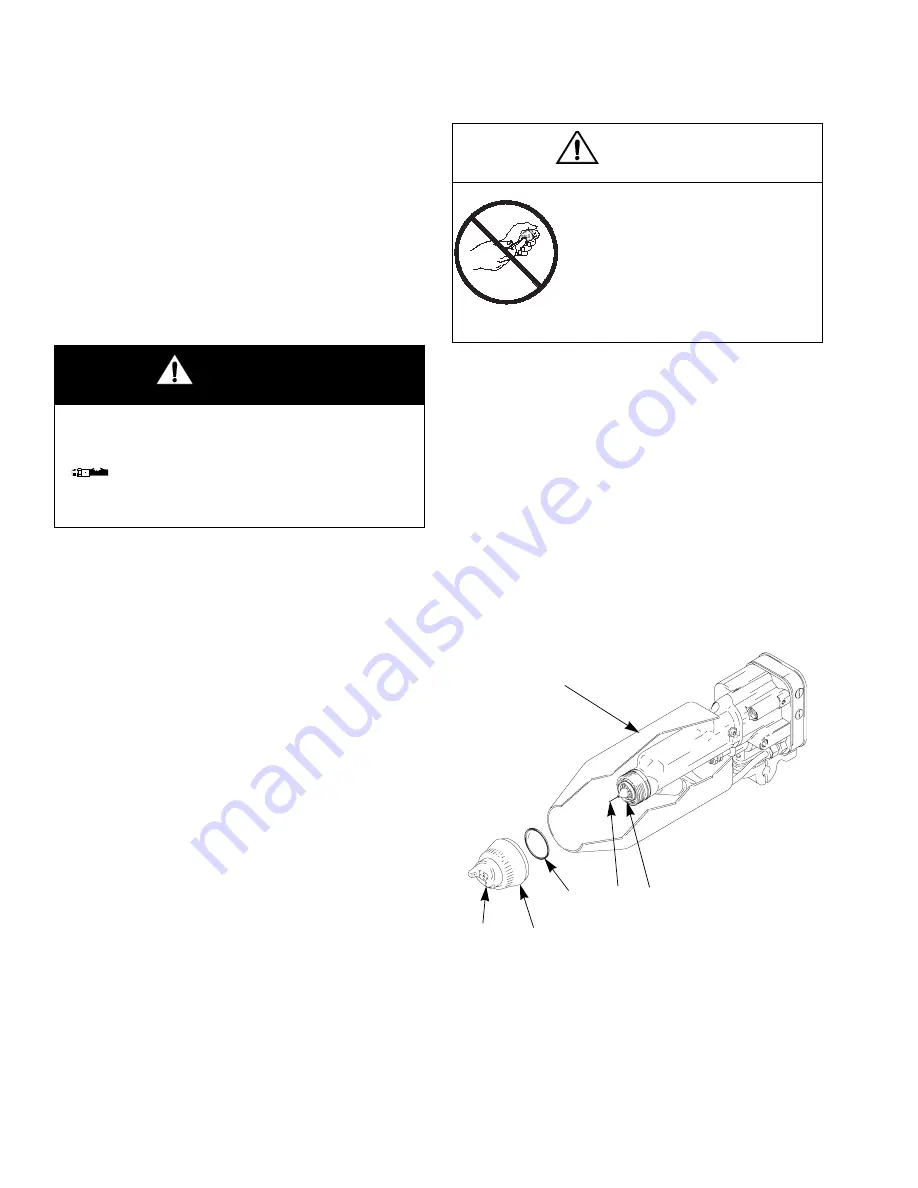

Clean the Air Cap and Fluid

Nozzle

Equipment Needed

•

soft bristle brush

•

compatible solvent

Procedure

1.

Relieve the pressure.

2.

Remove the air cap assembly (1, 3) and shroud (2).

See F

3.

Wipe the fluid nozzle (4), shroud (2), and exterior of

the gun clean with a cloth dampened in solvent.

Avoid getting any solvent into the air passages.

Whenever possible, point the gun down when clean-

ing it.

4.

If it appears that there is paint inside the fluid nozzle

(4) air passages, remove the gun from the line for

servicing.

5.

Clean the air cap (3) with the soft bristle brush and

solvent or submerge the air cap in suitable solvent

and wipe it clean.

6.

Slide the shroud (2) onto the gun.

7.

Carefully install the air cap (3). Be sure to insert the

electrode (7) through the center hole of the air cap.

Rotate the air cap to the desired position.

8.

Make sure the u-cup (1a) is in place on the retaining

ring (1). The lips must face forward. Tighten the

retaining ring until the air cap is held firmly in place;

you should not be able to rotate the air cap horns by

hand.

9.

Test gun resistance, page 26.

Fig. 13. Clean Air Cap and Fluid Nozzle

WARNING

Pressurized Equipment Hazard

To reduce the risk of an injury, follow the

Pressure Relief Procedure on page 17

when you stop spraying and whenever you

are instructed to relieve the pressure.

CAUTION

Do not use metal tools to clean the

air cap or fluid nozzle holes as this

could scratch them, and make sure

the electrode is not damaged.

Scratches in the air cap or nozzle or

a damaged electrode can distort the

spray pattern.

TI1560A

2

4

7

1

3

1a

Summary of Contents for PRO Auto Xs Series

Page 44: ...Repair 44 309297K Notes ...