9

307-043

Air Motor Service

7.

Pull the piston assembly (G) from the air motor

base (F), and set it aside.

8.

Remove the bearing housing assembly (26 or 27)

for all Models except Model 206–955. Remove and

wipe the seat clean with a cloth. For model

206–955, remove retainer ring (3) and bearing (4).

Remove seal (2, 27 or 28).

9.

Remove the base from the vise, and set it upright

on the workbench.

10. Place the piston rod flats in a vise.

11. Use a screwdriver to push down on the trip rod

yoke (O), and snap the toggles down. See Fig. 3.

WARNING

MOVING PARTS HAZARD

To reduce the risk of pinching or ampu-

tating your fingers, keep your fingers

clear of the toggle assemblies when you

are snapping the toggles (U in Fig. 3 ) up

or down.

12.

In this step, while you are prying with the screw

-

driver with one hand, cover the toggle assemblies

with your other hand so as to catch the spring-

loaded toggle assemblies when they snap out of

the lugs. Place the tip of a screwdriver into the

piston between the piston lugs (P) below the pivot

pins (Q) on the toggles, pry up with the screw-

driver handle to compress the springs on the

toggle assembly (U) up and away from the piston

lugs, and remove the parts. See Fig. 3.

13. Straighten the lockwires (L**) and remove them

from the upper valve nuts (J**). Screw the upper

valve nuts off. Remove the trip rod yoke (O),

actuator (V), and trip rod (C).

14. Unscrew the bottom valve nuts (K**), and remove

the poppets (N**). Make sure the valve bar spring

clips (W) are not worn or damaged and that they

properly guide the actuator (V).

15. Remove the exhaust valve poppets (M) by cutting

them with a side cutter, then pull them out of the

actuator (V).

16. Remove piston o-ring (Z) and internal base o-ring

(15** or 19**). Inspect o-rings.

17. Clean all the parts carefully in a compatible solvent

and inspect them for wear or damage. Use all the

repair kit parts during reassembly, and replace

other parts as necessary.

18. Check the surfaces of the piston, piston rod, and

cylinder wall for scratches or wear. A scored rod

will cause premature packing wear and leaking.

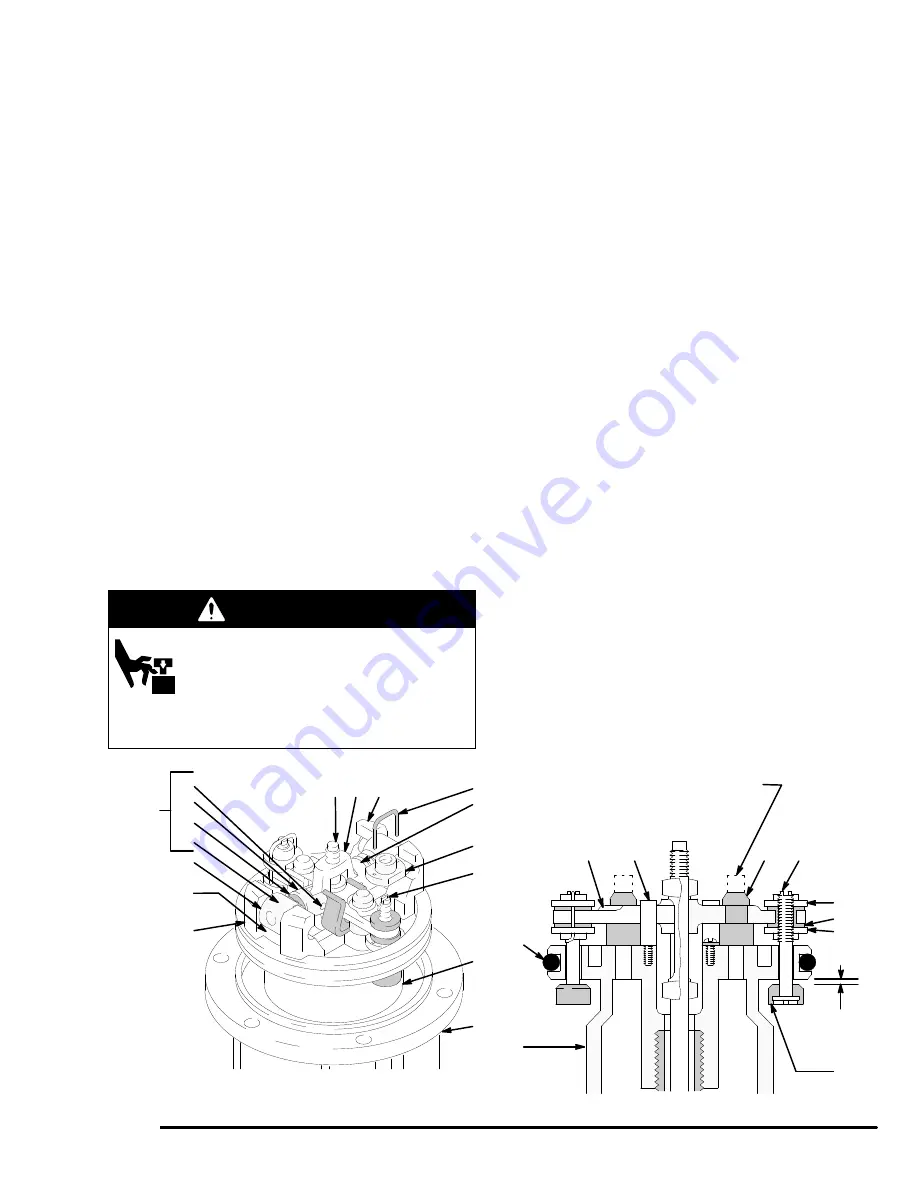

Fig. 3

04118

C O U

L

J

X

G

F

T

T

04119

W

V

G

M

X

J

K

N

0.145 in.

(3.7 mm)

P

Q

S

R

Z

U

Y

Cutaway View

Cut off the tops of the poppets

as indicated by the dotted lines

Z

Insert Screw

Driver Here