Operation

3A1334P

11

Step 6 is for Oil Pumps Only:

6.

The thermal relief feature of this oil pump can

increase the amount of time needed to fully prime

the pump when compared to pumps without a ther-

mal relief feature. To minimize this effect, prime the

pump

before

connecting it to an already primed dis-

tribution system.

7.

Read and follow the instructions supplied with each

component in your system.

8.

When shutting off the system and before checking

or servicing, relieve pressure following pressure

relief procedure, page 9.

Changing Grease Drum and Installing

Follow Plate (grease models only)

1.

Relieve pressure

, page 9.

2.

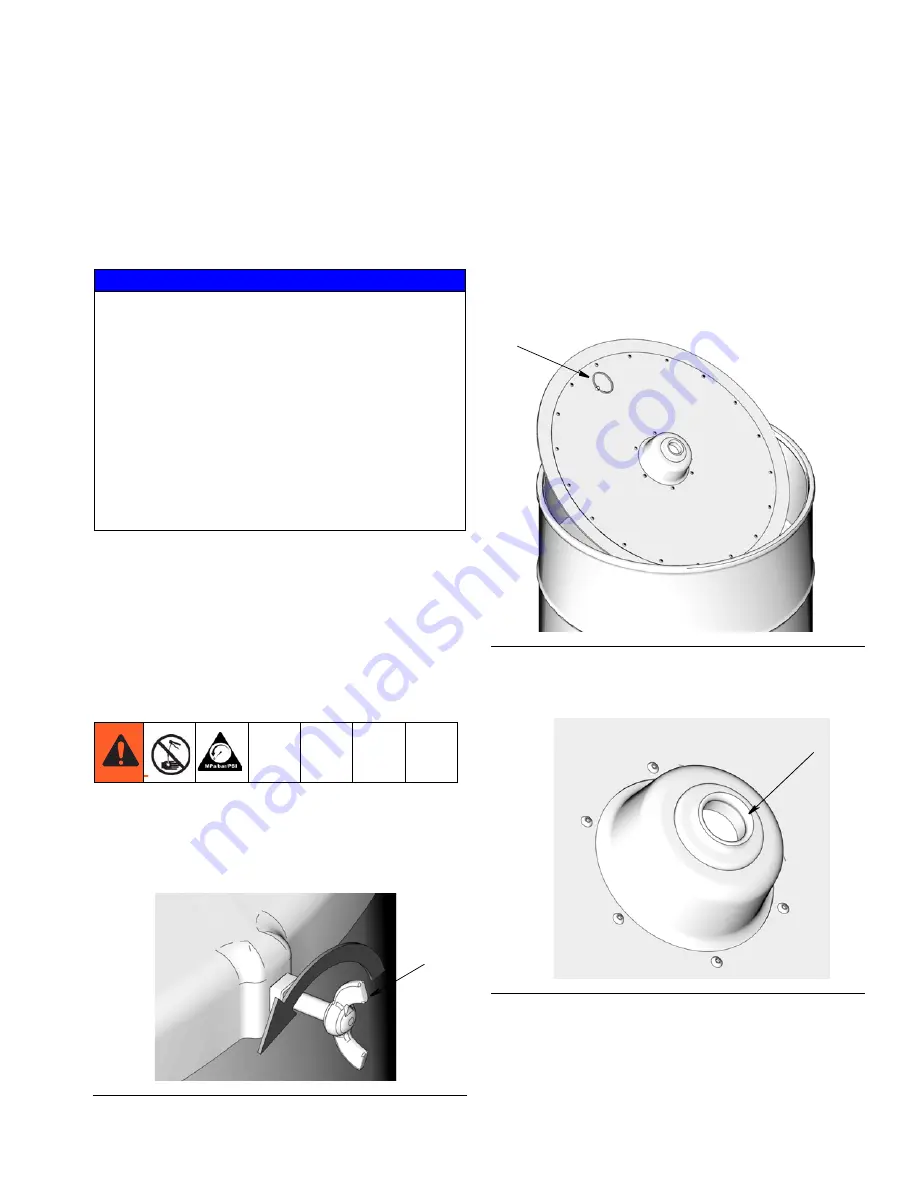

Remove drum cover by loosening thumb screws (a)

(F

IG

. 5).

3.

Remove pump and cover from drum and place on a

clean paper, cardboard, or clean shop rags. DO

NOT PLACE ON SHOP FLOOR.

4.

If this is an existing installation, reach into drum and

pull on follow plate ring (b) to remove follow plate

(F

IG

. 6). Place follow plate on a clean paper, card-

board or clean shop rags. DO NOT PLACE ON

SHOP FLOOR.

Remove drum and install new one.

5.

Examine follow plate to make sure rubber grommet

(c) is in place in center of the plate (F

IG

. 7).

6.

Set follow plate on top of fresh grease (F

IG

. 8).

Remove air by pushing on the follow plate until the

NOTICE

Never allow the pump to run dry of the fluid being

pumped. A dry pump will quickly accelerate to a high

speed, possibly damaging itself. If your pump acceler-

ates quickly, or is running too fast, stop it immediately

and check the fluid supply. If the supply container is

empty and air has been pumped into the lines, prime

the pump and lines with fluid, or flush it and leave it

filled with a compatible solvent. Be sure to eliminate

all air from the fluid system.

NOTE:

A pump runaway valve can be installed on the

air line to automatically shut off the pump if it starts to

run too fast.

F

IG

. 5

a

F

IG

. 6

F

IG

. 7

b

c

Summary of Contents for LD Series

Page 13: ...Notes 3A1334P 13 Notes ...

Page 31: ...Notes 3A1334P 31 Notes ...