WARNING

To reduce the risk of serious bodily injury, in-

cluding fluid injection, splashing in the eyes or on

the skin, or injury from moving parts, always

follow the Pressure Relief Procedure on page

when checking or servicing any part of the spray

when installing, cleaning or changing

spray tips, and whenever you stop spraying.

Flush the Pump Before Using

Pumps are tested with light weight motor oil which is

left

in to protect the pump parts.

To

prevent contamina-

tion of the fluid, flush the pump with a compatible

sol-

vent before using

it.

If the pump is being used to supply

a

circulating system, allow the solvent to circulate until

the pump is thoroughly flushed.

flushing pails are properly grounded. Refer to

Before

be sure the entire system end

Grounding on page

Follow the Pressure

Relief Procedure on page

2,

and

remove the

spray tip from the gun.

Always use the lowest

to-metal contact between the gun and the pail

possible fluid pressure, and maintain firm metal-

during flushing to reduce the risk of fluid injection

injury, static sparking and splashing.

GUN

AND CONTAINER

Starting and Adjusting the Pump

quid

before operating the pump to help prolong

Fill the wet-cup one-half full with Graco Throat Seal Li-

the packing life.

See

2. See

ACCESSORIES on page

to order TSL.

Trigger the spray gun into a grounded metal waste con-

tainer, -then slowly turn on the air regulator until the

pump begins to cycle, about psi

(2.8

Allow the

pump to cycle slowly until

all

air

is

purged from the fluid

the gun is flowing in a steady stream. Release the gun

lines. The lines are purged when the fluid emitted from

trigger; the pump will stall against pressure.

the pump and lines primed, and with adequate air

stop as the spray gun is triggered and released. In

a

pressure and volume supplied, the pump will

start

and

culating system,

it

will run continuously and speed up or

slow down as supply demands until the air supply is

shut

off.

pressure. Always use the lowest air pressure needed to

Use

the air regulator to control pump speed and fluid

produce the results you want. Higher pressures waste

fluid and cause premature wear of the pump packings

and

tip.

WARNING

To reduce the risk of serious bodily injury,

in-

cluding fluid injection, splashing in the eyes or on

the skin, and property damage, never exceed the

maximum air and fluid working pressure of the

lowest rated component in your system.

See

EQUIPMENT MISUSE HAZARD, System

Pressure, on page

Care

of

the Pump

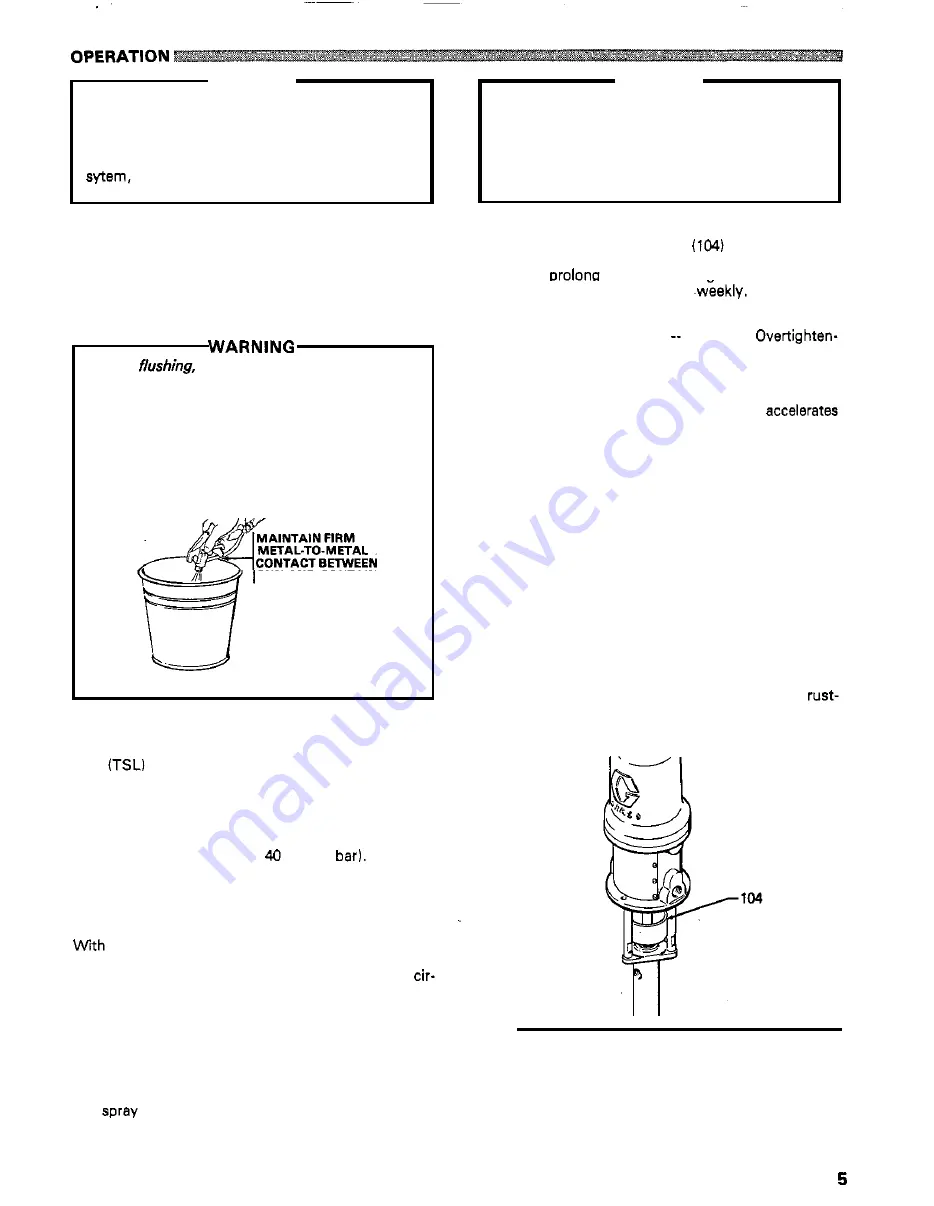

Keep the wet-cuplpacking nut

one-half full of

tect and

throat oackina life. Check the

Graco Throat Seal Liquid, see Accessories, to help pro-

tightness of the- packing nut

See Fig

ALWAYS

follow the Pressure Relief Procedure, on

page

2,

before adjusting the packing nut. Then tighten

it

just enough to stop leakage no tighter.

ing will compress and damage the packings.

pumped. A dry pump will quickly accelerate to a high

Never allow the pump to run dry of the fluid being

speed, and may damage itself. If your pump

quickly or is running too fast, stop

it

immediately and

check the fluid supply. If the supply container is empty

and air has been pumped into the lines, refill the supply

container and prime the pump, being sure to purge

ell

air

from the fluid system, or flush the pump as described in

Shutdown, below. A pump runaway valve automatical-

ly alerts you to this problem.

See

INSTALLATION.

Shutdown

Always follow the Pressure Relief Procedure on page

2,

whenever you shut off the pump.

Always stop the pump

at the bottom of its stroke to

keep fluid from drying on the exposed displacement rod

and damaging the throat packings.

Alwaysflush the pump with

a

compatible solvent before

fluid can dry in the pump and hoses. After flushing,

even for overnight storage, fill the pump with a

inhibiting solvent, such as mineral spirits, to prevent

corrosion, then relieve pressure.

Fig

2

307-619

Summary of Contents for HYDRA-SPRAY 218-058 A

Page 15: ...307 619 15...