308993 11

Operation

Adjust the Spray Pattern

WARNING

INJECTION HAZARD

To reduce the risk of component rupture

and serious injury, including injection, do

not exceed the gun’s maximum fluid

working pressure of 1500 psi (10 MPa, 105 bar) or

the maximum working pressure of the lowest rated

component in the system.

WARNING

COMPONENT RUPTURE HAZARD

Do not exceed the

maximum fluid and

air pressure

of this gun. Higher pressur-

es can cause parts to rupture and result in serious

injury.

1.

Do not turn on the air supply yet. Set the fluid

pressure at a low starting pressure. For low vis-

cosity fluids (less than 25 sec, #2 Zahn cup) with

lower percent solids (typically less than 40%), start

at 300 psi (2.1 MPa, 21 bar) at the pump outlet.

For fluids with higher viscosity or higher solids

content, start at 600 psi (4.2 MPa, 42 bar). If a

fluid pressure regulator is installed, use it to make

the adjustments.

If your system does not have a fluid regulator,

such as a Falcon I or Falcon II package, the fluid

pressure is controlled by the air regulator supplying

the pump. See the example below.

Example:

Pump Ratio

x

Pump Air Regulator

Setting

=

Fluid

Pressure

Falcon I

(10:1 ratio)

x

30 psi (0.21 MPa,

2.1 bar)

=

300 psi

(2.1 MPa,

21 bar)

Falcon II

(20:1 ratio)

x

30 psi (0.21 MPa,

2.1 bar)

=

600 psi

(4.2 MPa,

42 bar)

2.

Trigger the gun to check the atomization; do not be

concerned about the pattern shape yet.

3.

Increase the fluid pressure in 100 psi (0.7 MPa, 7

bar) increments, just to the point where a further

increase in fluid pressure does not significantly

improve fluid atomization. See the example below.

Example:

Pump

Ratio

x

Pump Air Regulator

Setting (increments)

=

Fluid

Pressure

(increments)

Falcon I

(10:1

ratio)

x

10 psi (0.07 MPa,

0.7 bar)

=

100 psi

(0.7 MPa,

7 bar)

Falcon II

(20:1

ratio)

x

5 psi (0.035 MPa,

0.35 bar)

=

100 psi

(0.7 MPa,

7 bar)

4.

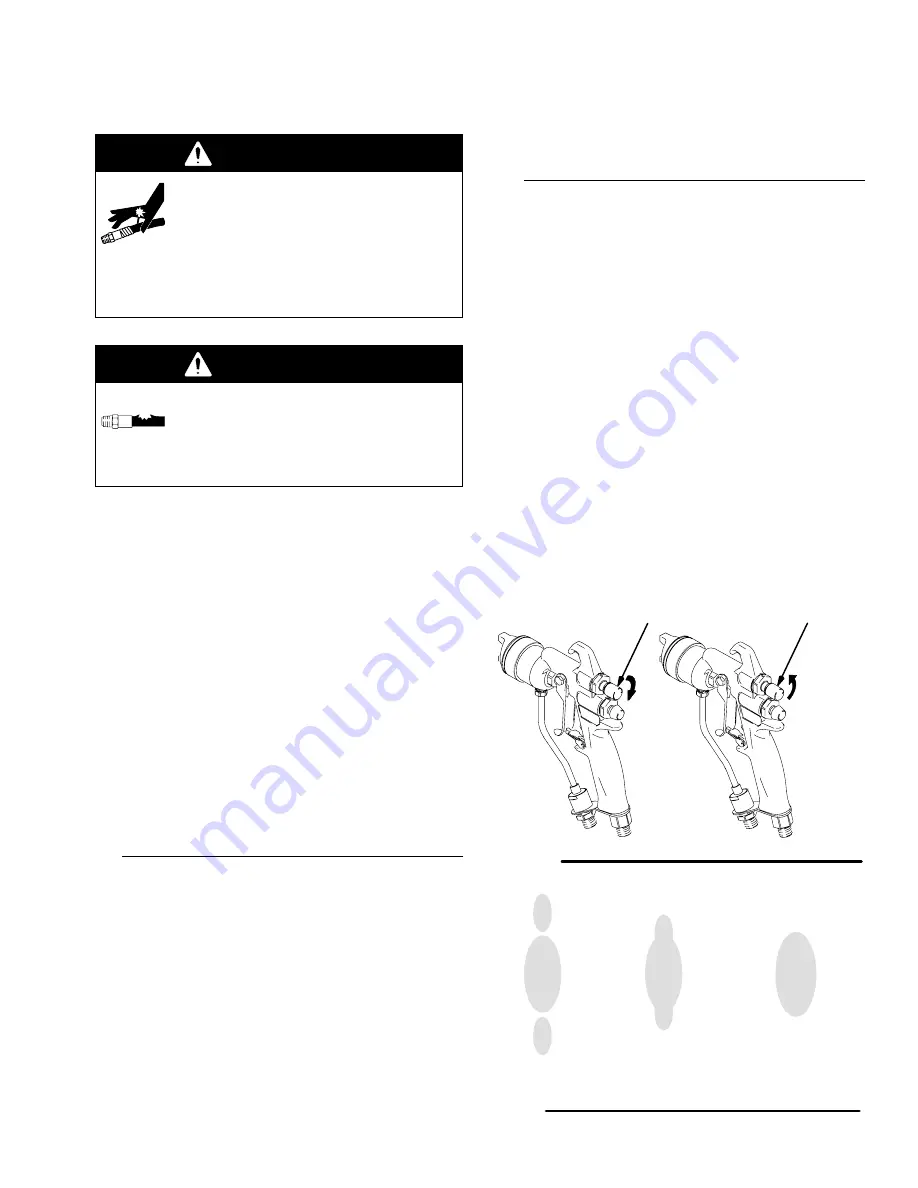

Close off the pattern adjustment air by turning the

knob (S, see Fig. 5) clockwise (in) all the way. This

sets the gun for its widest pattern.

5.

Set the atomizing air pressure at about 5 psi (0.35

bar, 35 kPa) when triggered. Check the spray

pattern, then slowly increase the air pressure until

the tails are completely atomized and pulled into

the spray pattern. See Fig. 6. Do not exceed 100

psi (0.7 MPa, 7 bar) air pressure to the gun.

For a narrower pattern,

turn the pattern adjustment

valve knob (S, see Fig. 5) counterclockwise (out).

If the pattern is still not narrow enough, increase

the air pressure to the gun slightly or use a differ-

ent size tip.

ÎÎ

ÎÎ

ÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

ÎÎ

ÎÎ

ÎÎ

ÎÎÎ

ÎÎÎ

ÎÎÎ

9131A

Fig. 5

S

Out

(narrower

pattern)

In

(wider

pattern)

S

No Air

Too Little Air

Right Amount

of Air

Fig. 6

0792

Summary of Contents for 241508

Page 4: ...4 308993 Notes...