Installation

Install the printer

1. Please put the printer on the stable surface.

2. Make sure printer power is turned off, please do not plug

the power cable when the printer power is turned on.

3. Connect serial or USB or Parallel or Ethernet cable to

printer and PC.

4. Connect power plug to power supply socket.

Be careful:

※

Please turn off the power switch the printer in the power socket,

※

Transmission interface in the picture will vary depending on your printer

purchased aircraft type, the actual transmission interface, please refer to

the corresponding product specifications

power line is inserted into the printer.

<Picture 6>

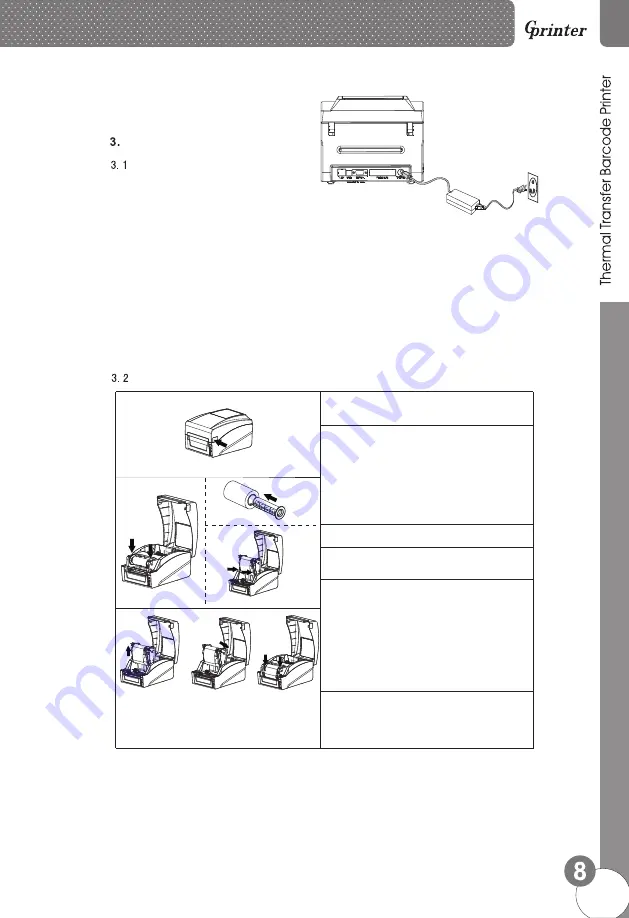

Ribbon installation

1. Press two press buttons on left and right side to open

printer

top

cover.

2. Put empty paper tube into ribbon take-up hub if you

buy new ribbon which one side is no contact with

paper tube. After that, install ribbon take-up hub left

side and right side onto printer.

Remark: Factory standard ribbon two sides already

fixed well on paper tube. Go ahead to step 3 instead

of step 2.

3. Press the Push button to open print head.

4. Insert black ribbon supply hub into new ribbon, then

install ribbon and supply hub from left to right side.

5. If insert factory supplied new ribbon, please refer to

step 2: install ribbon and ribbon take-up hub.

If you buy and use new ribbon, firstly you roll up the

ribbon onto the empty paper tube.

After that please adjust the big blue wheel according

to the direction of arrows to assure the ribbon touch

the take-up hub flatly and smoothly without wrinkle.

6. Close print head by pressing two arrows locations,

confirm the two sides of print head are closed

correctly to ensure you get printing in good quality.

(Pic 1)

(Pic 2)

(Pic 4)

(Pic 5)

(Pic 6)

(Pic 7)

(Pic 8)