JSV3H

OM−05229

MAINTENANCE AND REPAIR

PAGE E − 9

2.

Inspect all mating surfaces and the rotor/shaft

assembly for nicks or burrs, and restore to

original contours with emery cloth or a fine file.

If the surface cannot be restored, replace the

part.

Cleaning Seal Assembly

Seal faces are precision-finished and sub-

ject to wear patterns which cannot be re-

aligned during assembly. The seal assem-

bly should be replaced completely at each

overhaul to ensure trouble-free operation.

If necessary to use an old seal in an emer-

gency,

never

mix old and new seal parts;

seal performance will be severely affected.

1.

Inspect the seal assembly for wear, scoring,

grooves, and other damage that might cause

leakage.

2.

Wash all seal parts in fresh cleaning solvent

and allow to dry thoroughly. Re-inspect the

parts after cleaning.

3.

If needed, clean the seal faces with a clean,

lint-free tissue. Wipe lightly in a concentric pat-

tern to avoid scratching the faces.

PUMP AND MOTOR REASSEMBLY

MOTOR REASSEMBLY

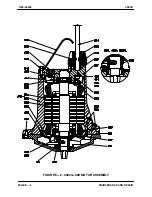

References are to FIGURE E−2.

Installing Bearings

NOTE

The bearings in this pump are permanently lubri-

cated.

When installing the upper bearing (203) on

the shaft,

never

press or hit against the

outer race, balls, or ball cage. Press

only

on the inner race. A sleeve with the same

diameter as the inner race is useful for in-

stalling the bearing.

When installing the lower bearing (207) in

the bearing housing,

never

press or hit

against the inner race, balls, or ball cage.

Press

only

on the outer race. A sleeve with

the same diameter as the outer race is use-

ful for installing the bearing.

1.

Lightly oil the upper and lower ends of the ro-

tor/shaft assembly (201).

NOTE

Heating the bearings will ease installation.

Never

heat bearings by direct flame

.

An induction

heater, hot oil bath or electric oven may be used.

If a hot oil bath is used to heat the bearings, both the

oil and the container must be absolutely clean, and

if the oil has been previously used, it must be thor-

oughly filtered.

Use tongs, insulated gloves, or other

protective devices when handling

heated bearings.

NOTE

Do not heat the bearings until ready to install. Heat it

to a uniform temperature no higher than 250

_

F

(120

_

C), and slide the bearings onto the shaft in

one continuous motion to prevent cooling and

sticking.

2.

Slide the upper bearing (203) onto the shaft

until it seats squarely against the shaft shoul-

der.