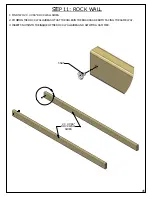

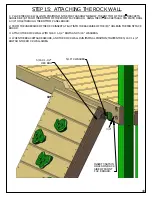

TORQUE WASHER

3/8" WASHER

3/8" LOCK NUT

BOLT CAP

7" CARRIAGE BOLT

3/8 X 3-1/2"

LAG SCREW

1: FASTEN THE SWING BEAM TO THE SWING BEAM BRACKET USING 7" CARRIAGE BOLTS WITH TORQUE WASHERS ON

TOP OF THE SWING BEAM, AND 3/8" LOCK NUTS WITH 3/8" WASHERS FROM UNDERNEATH.

2: USE A 3/8 X 3-1/2" LAG SCREW WITH 3/8" WASHER FOR THE HOLE IN THE CENTER OF THE SWING BEAM BRACKET.

3: PLACE A BOLT CAP OVER ANY EXPOSED THREADS.

STEP 24: MOUNT SWING BEAM TO SWING BEAM LEGS

58

Summary of Contents for 1500CTC

Page 6: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 9: ...REAR VIEW FRONT VIEW ...