Contact

an

Authorized

Golden

Eagle

Pellet

Stove

Dealer

to

obtain

any

of

these

parts.

If

your

dealer

does

not

stock

parts

you

can

purchase

parts

direct

from

our

website

at

www.goldeneaglestoves.com

.

Never

use

substitute

materials.

Use

of

non

‐

approved

parts

can

result

in

poor

performance

and

safety

hazards,

and

will

void

your

warranty.

ITEM

PART

#

Air

Switch

C

‐

E

‐

201

Air

Switch

Hose

C

‐

M

‐

340

‐

T

Auger

Motor

C

‐

E

‐

017

Maintenance

Tool

A

‐

TOOL

‐

96

Burnpot

A

‐

S

‐

BURNPOT

Circuit

Board

/

Control

Panel

A

‐

E

‐

401GE

Combustion

Blower

A

‐

E

‐

027

Convection

Blower

A

‐

E

‐

033A

Door

Gasket

C

‐

G

‐

050

Door

Glass

–

GE400

‐

01

Version

C

‐

D

‐

11000

Door

Glass

–

GE400

‐

02

&

03

&

04

&

05

Versions

C

‐

D

‐

031

Exhaust

Adapter

3”

C

‐

M

‐

050

Exhaust

Adapter

4”

A

‐

4

‐

VA

Gasket

‐

Door

C

‐

G

‐

055

Gasket

–

Combustion

Blower

Housing

to

Stove

C

‐

G

‐

101

Gasket

–

Combustion

Blower

Motor

to

Housing

C

‐

G

‐

105

Hot

Rod

Igniter

C

‐

E

‐

IGN

Thermodisk,

Proof

of

Fire

C

‐

E

‐

090

‐

22C

Thermodisk,

High

Temp

C

‐

E

‐

090

‐

21

Damper

Knob

C

‐

M

‐

013

Window

Gasket

C

‐

G

‐

033

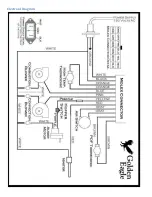

Summary of Contents for Talon

Page 34: ...Electrical Diagram ...