Deutsch |

2

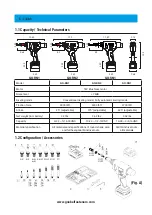

4. Tool Operation (Important tips before starting work)

English |

16

4.2 Checking the set blind rivet nut

If after the setting process the result of the blind rivet nut setting appearance does not

correspond to the picture in the middle, it shows that the stroke has not been set to the

most suitable setting. Further fine adjustment can be made by adjusting (+/-) with the

tool wrench (see illustration). If the fine adjustment does not lead to the desired goal,

please check/perform instruction 3.2 Adjusting the stroke again.

4.3 Unscrewing blind rivet nuts manually

Important note: Too high a traction force or a too long working stroke (incorrect

setting) can damage the blind rivet nut thread. In addition, the wrong setting can cause

the thread of the blind rivet nut to become severely deformed and the automatic

unwinding of the blind rivet nut is blocked. The blind rivet nut has caught and is still

seated on the mandrel. Use the Allen key to unscrew the blocked blind rivet nut

manually.

Remove the battery according to figure

①

, unscrew the protective cap in the direction

of the arrow to remove the protective cap, insert the Allen key into the hexagonal hole

at the rear end in the direction of the arrow in figure

➂

, loosen the blind rivet nut

blocked by the threaded mandrel counter clockwise in the direction of the arrow in

figure

④

. Install the battery in figure

⑤

, see figure

⑥

, the threaded mandrel extends

automatically after pressing the release button.

www.goebelfasteners.com