3. Printer Setting

3-1. FEED Key

After pressing the FEED key, printer will feed the media (according to media type) to the

specified stop position. When printing with continuous media, pressing the FEED key will feed

the media out to a certain length. When printing with labels, the printer will feed one label each

time the FEED key is pressed. If the label is not sent out in a correct position, please proceed

with the Auto Sensing (see next section).

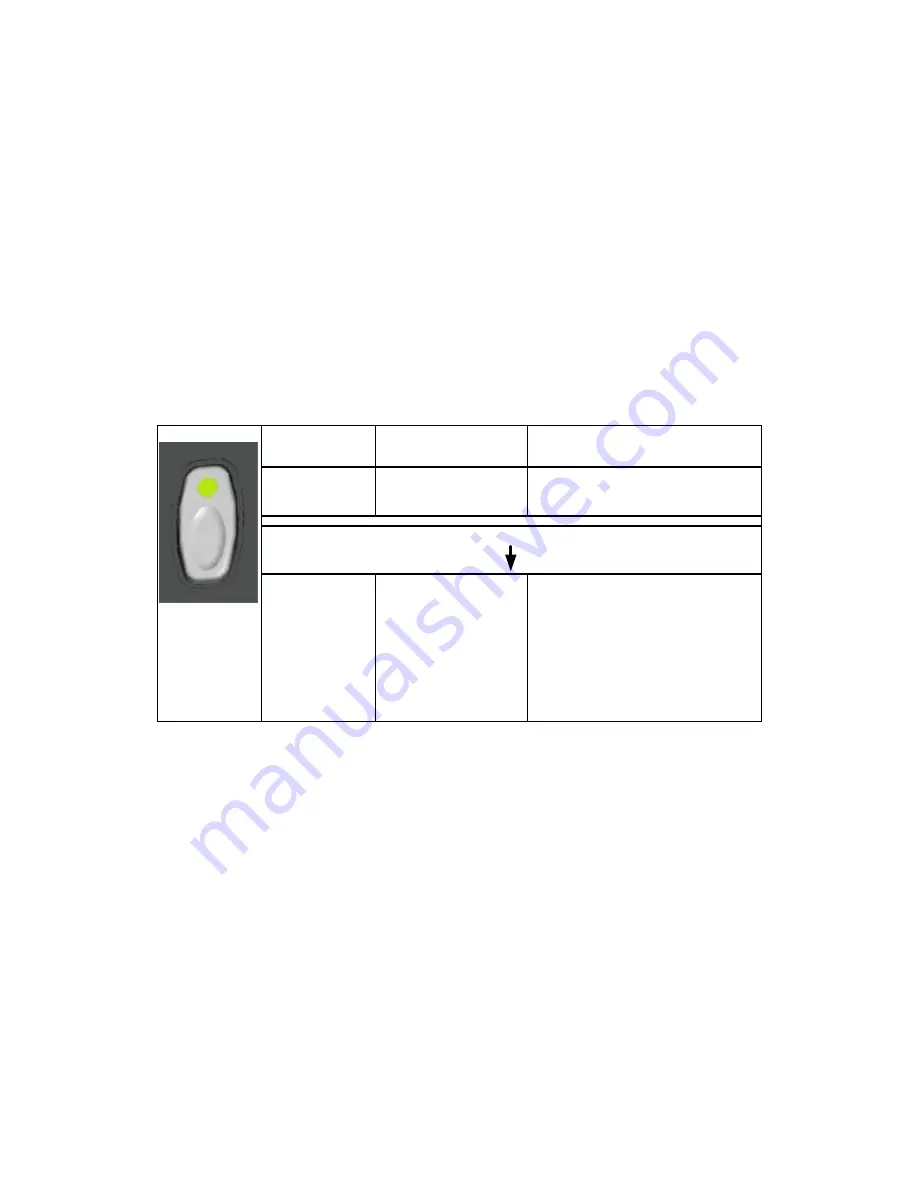

3-2. LED Status

*Note: below descriptions are only applied on firmware version G3.000 or after.

Press and hold the FEED key then power on the printer. Wait for the LED light flashing red and

then release the FEED key, the printer will enter into Auto Sensing Mode to do the calibration. A

Self-Test page will be printed out automatically after the calibration is completed. Below are the

sequence and the description of two modes:

LED Light

Status

Description

Green

Standby Mode

Normal status

Press and hold the FEED Key then power on the printer.

Red (Flash)

Auto Sensing Mode

Printers are currently in Auto

Sensing Mode. The calibration will

be performed and a Self-Test page

will be printed out to show the

configurations of printer. For more

detail about Auto Sensing Mode,

please refer to next section. For the

descriptions of Self-Test page

please refer to page 18.

3-3. Auto Sensing

Printer can automatically detect the label and store the result of detecting. By doing this, the

printer will calibrate the printing position of the label and the user can do printing without setting

the label length. To perform the Auto Sensing, please do as follows:

1.

Check if the label is correctly loaded on the printer.

2.

Power off the printer, press and hold the FEED key.

3.

Power on the printer while still holding the FEED key. Keep holding the FEED key, wait for

the LED light turn to flash red and then release the FEED key. Printer will automatically

detect the label and record it.

4.

A Self-Test page will be printed out after Auto Sensing is completed and the printer goes

back to standby mode.

EZ-1105 / EZ-1305 User’s Manual

17