3

1.

General Information

The Level Wind is a chain driven device specifically designed to distribute wire rope coils or

wraps evenly across the winch drum.

Level winding the wire rope onto the drum has several advantages:

●

Increases drum storage capacity.

●

Prevents wire rope pileup.

●

Permits smooth, steady pulls.

●

Establishes tight, even wraps preventing the wire rope from cutting down through the lower

lays resulting in damage to the rope and difficulty in unwinding.

2.

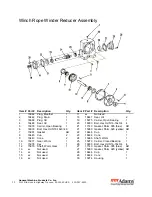

Description

The level wind assembly includes a carriage/roller cage, guide bars, speed reducer, two single

width and one triple width roller chain drive.

The carriage is mounted on two guide bars and is driven side to side across the drum by an end-

less triple width cross chain (

See Figure 1 on page 2

).

The carriage is connected to the cross chain by a drive pin which projects into a vertical slot in

the carriage. As the cross chain rotates, it carries the drive pin and the carriage across the drum.

When the drive pin reaches the end sprocket, it rotates around the sprocket moving up or down

in the slot as required. Accordingly, the carriage and wire rope moves to the end of its travel and

starts back again across the drum.

Positioned above the carriage (or below in the under wind configuration) is the roller cage as-

sembly thru which the wire rope passes for final storage on the drum. The rollers are shielded

with a roller guard for the purpose of operational safety.

3.

Operation

The level wind is mechanically driven from the motion of the winch drum. Use caution to maintain

uniformity and compactness of the wraps and lays of the wire rope on the drum at the start of the

pull.

The carriage remains properly aligned because the level wind is mechanically driven directly

from the winch drum. This is true of whether the rope is paying onto the drum under power or

paying out under free spool conditions.

The speed of the carriage is regulated. For each revolution of the winch drum, the carriage ad-

vances across the drum a distance equal to the diameter of the rope.

Initially, the correct sprockets are determined by the factory relative to the nominal cable size

that is specified for the winch. Due to minor variations in the diameter of the wire rope, the aver-

age diameter may have to be determined in order to modify the speed of the rope winder. Take

several diameter measurements along the length of the wire rope, and call GMP to determine

the correct sprocket combination.

Once a given set of sprockets has been established for a specific wire rope diameter, the rope

diameter cannot be changed without a change in the sprocket teeth combination.

Constant tension must be maintained on the rope when operating the level wind.

The

amount of tension should be sufficient to eliminate

“

clock springing

”

that will lead to loose or tan-

gled wraps and lays.

Under free spool conditions, if the drum has been permitted to over

-

run, resulting in loose or tan-