10

General Machine Products Co. Inc.

3111 Old Lincoln Highway Trevose, PA 19053 USA

215

-

357

-

5500

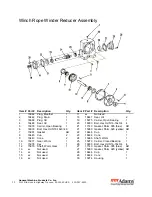

Item

No.

Part

No.

Description

Req

’

d

Qty.

1

26459

26460

Carriage assembly (CD3 over wind, WG over and under wind)

Includes items 2A, 3A, 4, 5, 6 Assy

Carriage assembly (CD3 under wind)

Includes items 2A, 3A, 4, 5, 6 Assy

1

1

2

25869

25870

Roller Assembly (WG, CD3 over wind)

Roller Assembly (CD3 under wind only)

2

2

3

25858

25862

Shaft (WG, CD3 over wind)

Shaft (CD3 under wind only)

2

2

4

25848

Guide Roller

1

5

25850

Shaft Guide Roller

1

6

09983

Roll pin

1/4”

x

2”

Long

2

7

14926

Guide Plate

2

8

16755

Cap Screw Hex Hd 3/8

-

24 x

2”

Long

4

9

16449

3/8”

Lock washer SAE medium

4

10

29764

34336

WG Cross Chain Assembly 5/8 Pitch 60 Pitches Triple

Width Roller Chain, Includes Items 11 & 12

CD3 Cross Chain Assembly 5/8 Pitch 74 Pitches Triple

Width Roller Chain, Includes Items 11 & 12

1

1

11

14952

Guide Link

1

12

14951

Connecting Pin

2

13

14927

Driving Pin

1

14

16938

Cap Screw Hex Head 1/2

-

20 x 2 ½

”

4

15

17591

Nut Hex 1/2

-

20

4

16

09324

1/2”

Lock Washer SAE medium

5

17

17575

Nut Jam Steel 1/2

-

13

3

18

16762

Collar W/Set Screw

1

19

15585

Bracket Assembly w/Item 21

2

20

Same as item #19

21

16723

Bushing Oilite For Item 19

2

22

14949

14972

Sprocket w/Set screw 40 Teeth for

7/16”

,

1/2”

wire rope

Sprocket w/Set screw 36 Teeth for

5/16”

,

3/8”

,

9/16”

wire rope

1

23

14925

Sprocket 10 Teeth,

5/8”

Pitch Triple Width

Roller Chain, Short

1

24

14924

Sprocket 10 Teeth,

5/8”

Pitch Triple Width

Roller Chain, Long with keyway

1

25

16734

Woodruff Key

5/16”

x

1”

For Items 22 & 24

1 EA.

26

14973

Washer, Thrust (spacer)

2

27

09043

Nut, Jam

5/8”

-

18

2

28

17837

Cap Screw Hex Head 1/2

-

20 x 1 ¾

”

10

29

26061

Guide Rod Support

1

30

14915

24211

Sprocket (Replacement) For Winch Drum 58 Teeth

5/8”

Pitch Roller Chain

Sprocket as above split for replacement on mounted winch. Must be welded in place

1

1

31

15593

Idler Bracket Assembly Second Reduction

Includes:

1 #14965 230

-

1003 Idler Bracket

2 #16724 110B Oil Cup

1 #16746 AA1110

-

12 Bushing Oilite

1 #16747 AA1108

-

16 Bushing Oilite

1

Refer to Drawing # 30435 on Page 9