Page 27

2669-RT / 3369-RT / 4069RT

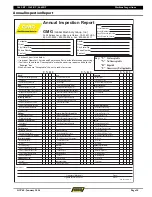

Pre-Start Inspection Checklist

The operator must conduct a Pre-Start Inspection of the machine before each work shift.

DO NOT use a damaged or malfunctioning machine.

Initial

Description

_______

Check that the operator’s manual and manual of responsibilities are in the storage container located on the platform.

_______

Perform a visual inspection of all machine components. Look for missing parts; torn or loose hoses; hydraulic fluid

leaks; loose, torn or disconnected wires; damaged tires; etc.

_______

Check all structural components of the machine for cracked welds, corrosion and collision damage.

_______

Check all hoses and the cables for worn or chafed areas.

_______

Check the platform rails and personnel entry for damage or modification. Check for missing spring pin retainers.

_______

Check that all warning and instructional decals are present, legible and secure.

_______

Check the tires for damage.

_______

Check the tire pressure (not required for foam filled tires).

_______

Check that all structural components, pins and fasteners are present and properly tightened.

_______

Check for fluid leaks.

_______

Check hydraulic fluid level (check with platform fully lowered).

_______

Check that battery is clean and secure. Check terminals for proper tightness. Check for corrosion.

_______

Check engine coolant level in coolant recovery bottle.

_______

Check engine oil level.

_______

Secure all covers, panels and guard rails.

_______

Ensure that the personnel entry is properly closed and secured before operating the machine.

Consult the Kubota engine manual for details regarding other engine checks and change intervals for filters and fluids.

1

OP69

– January 2018

Machine Inspections