4.6 Installation procedure

IMPORTANT.

With regards to the Manual Handling

Operations, 1992 Regulations, the following lift operation

exceeds the recommended weight for a one man lift.

Unpack the Glow-worm cylinder and check the contents refer

to section 3.

NOTE:

Position the Glow-worm cylinder in accordance with

section 4.1 Siting.

4.7 Central Heating pipework

To prevent the Glow-worm cylinder from overheating the 2

port motorised valve supplied with the cylinder must be fitted

to the Central Heating flow to the indirect coil, see diagram

4.4.

4.8 DHW system Pipework

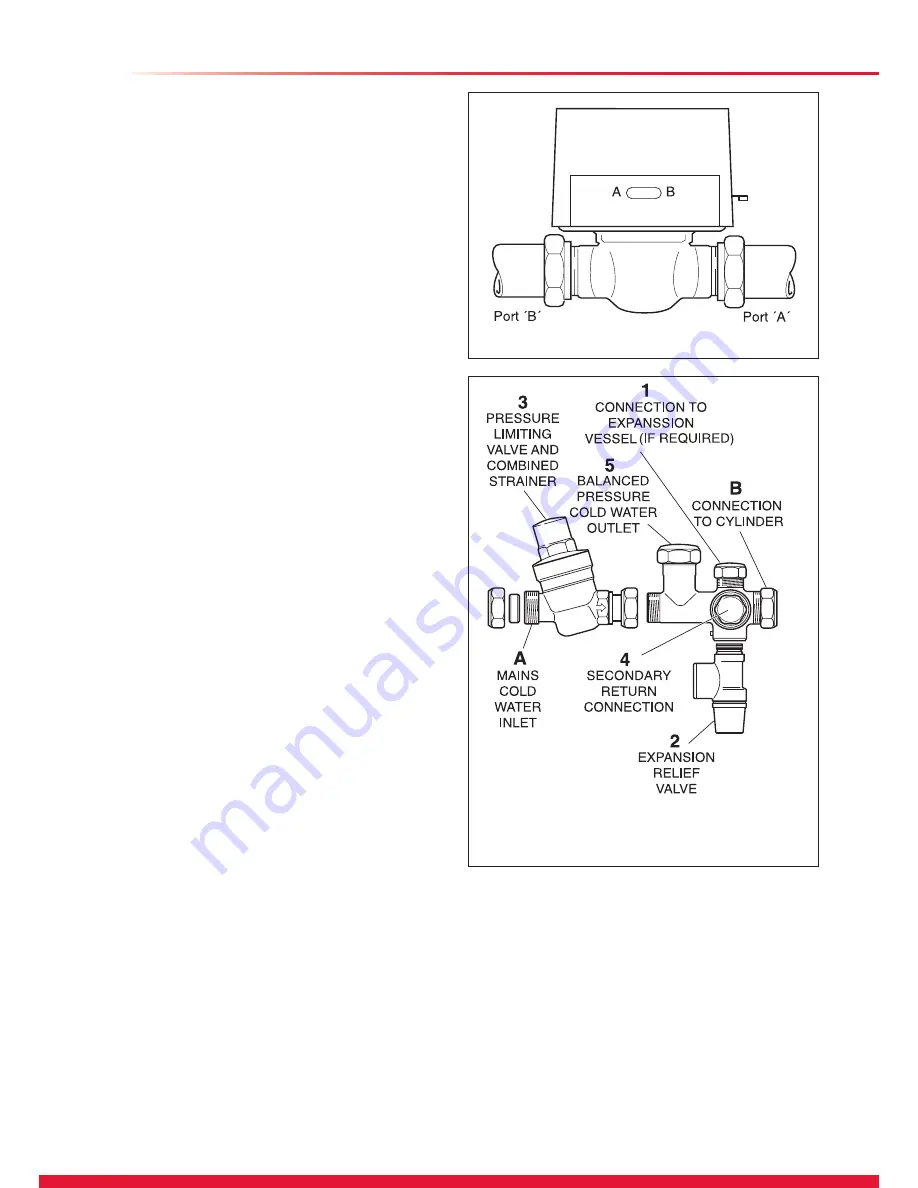

Connect the two cold water control valves together as shown

in diagram 4.7, ensuring that the orientation of the valves,

when installed in the cold mains supply, allows the 15mm

outlet of the expansion relief valve to be connected to the

tundish.

Install the discharge pipe from the expansion relief valve so

that it has a continuous fall to outside in a safe and visible

position where it will be unaffected by frost.

Never cap or block the outlet of the expansion relief valve.

Activate the expansion relief valve regularly to prevent from

calcification.

Provide a cold water mains supply to the Glow-worm cylinder.

To ensure optimum performance from the Glow-worm

cylinder, and particularly in installations where the balanced

pressure cold water outlet (5, diagram 4.7) is to be used, the

pipework provided from the building mains stop valve to the

Glow-worm cylinder should be minimum 22 mm copper tube.

Install a drain valve in the cold mains supply between the

Glow-worm cylinder and the cold water control valves at the

lowest point.

Install the assembled cold water control valves, see diagram

4.7 in the cold mains supply at a convenient position adjacent

to the Glow-worm cylinder, ensuring adequate space exists

for service access and allow for connection of the discharge

pipe from relief valves.

The discharge pipes should be discharging either directly or

via a manifold to a tundish. The relief valves must be within

600 mm of the tundish, see diagram 4.5.

The Glow-worm cylinder is provided with an external

expansion vessel.

Connect the expansion vessel to the installed water controls

by either:

i.

Screwing the vessel directly into the control assembly at

the purpose provided connection (4, diagram 4.7) or,

ii.

Connecting the vessel to the control assembly via

copper pipe or a suitable approved flexible connection hose,

ensuring that the vessel is adequately supported (1, diagram

4.7).

NOTE:

An optional ”Remote Expansion Vessel Mounting Kit”

is available for use with Glow-worm cylinders (Accessory No.

0020000000). The kit contains a wall mounting bracket.

Connect the balanced pressure cold water supply (if required)

to the cold water control pack, see diagram 4.7.

NOTE:

In areas where the mains water pressure is high (4

bar or above) the cold water supply to a bath or shower mixer

valve can be taken from the balanced pressure cold water

outlet (5, diagram 4.7) of the cold water controls. This will

ensure that both hot and cold supplies to the mixer valve are

at approximately the same pressure. The cold water supply

for all other terminal fittings should be tee'd into the cold water

supply pipework to the Glow-worm upstream of the cold water

controls.

4 Installation

IMPORTANT:

No isolation valve shall be installed between

the assembled cold water control valves and the cylinder.

12555

12556

Connect the DHW outlet pipework to the 22 mm domestic hot

water outlet on the Glow-worm cylinder. Continue with 22 mm

size pipe to the first tee fitting after which 15 mm pipework

should be adequate. If the pipe runs are of excessive length or

there are several terminal fittings supplied, extend the length

of pipework in 22 mm.

Connect the secondary return if required, as described in

section 3.2 Secondary Return.

4.9 Safety valve discharge pipework

Connect the temperature/pressure relief and expansion

relief valves to the tundish using 15mm pipe and install the

discharge pipework from the tundish in accordance with

section 4.4 Discharge Pipework.

Diagram 4.6

Diagram 4.7

12

Summary of Contents for SS 115

Page 11: ...4 Installation FUNCTIONAL DIAGRAM 12553 FUNCTIONAL DIAGRAM 12554 Diagram 4 4 Diagram 4 5 11 ...

Page 16: ...12560 Diagram 7 1 FAULT A 7 Fault Finding 16 ...

Page 17: ...12561 Diagram 7 2 FAULT B 7 Fault Finding 17 ...

Page 18: ...7 Fault Finding 12564 FAULT C Diagram 7 3 18 ...

Page 19: ...7 Fault Finding 12562 FAULT D Diagram 7 4 19 ...

Page 20: ...20 ...

Page 21: ...21 ...

Page 22: ...COMMISSIONING CHECKLIST MAINS PRESSURE HOT WATER STORAGE SYSTEM ...