2 ·

· 3

MANUAL | VA10J&X | VS10C | VA10C | ATEX certified

MANUAL | VA10J&X | VS10C | VA10C | ATEX certified

Congratulations with your GLOBE air motor!

This product is made with quality materials to meet the highest standards.

This manual contains safety instructions for the use of your GLOBE air

motor. Please read and follow all recommended instructions for a trouble-

free use.

Warranty

The GLOBE air motor is designed to operate without any problems. This is only guaranteed if the

regulations with regards to installation, operation, maintenance and repair are observed. Problems

occurring during the guarantee period are corrected in accordance to GLOBE Airmotors BV

guarantee conditions. All results of unauthorized replacements and alterations are at the operator’s

expense. In case of unauthorised opening and repair work carried out during guarantee period by

the operator, the guarantees may become invalid.

You can order your service kit at [email protected]. Please ensure that maintenance is carried

out by certified staff.

Safety first

Safety is important for you and other people. For the protection of you and others, we have several

warnings in this manual and on the product. Please always read carefully and follow the instructions.

STOP

Hazard

Possible consequences: dead or

severe injuries

Dangerous situation

Possible consequence: damage

to the drive of the environment

Wear hearing protection

Wear eye protection

Important instructions

on protection against

explosion

Hazard Situation

Possible consequences: slight or

mild injuries

APPROVALS

ATEX CERTIFICATION

II 2G Ex h IIC T4 Gb

II 2D Ex h IIIC T135°C Db

The GLOBE vane air motors are ATEX certified

according to the following (harmonized)

standards:

EN-ISO80079-36:2016

EN-ISO80079-37: 016

The motors are marked with the following EX

marking:

In which:

II

2G

2D

Ex h

IIC

IIIC

T4

T135°C

Gb

Db

Ta

Equipment group II for use above ground

Category 2G for use in Zone 1 or 2

Category 2D for use in Zone 21 or 22

Protection by constructional safety “c” Gas

group IIC

Dust group IIIC

Temperature class T4

Maximum surface temperature 135°C

Equipment protection level Gb

Equipment protection level Db

Ambient temperature range

Ta = - 20° + 60°C

Contents

Warranty 3

Safety first

3

Checklist to comply to ATEX

4

Installation

5

Mounting to construction

5

Air supply

6

Operation

8

Performance regulation

10

Maintenance

11

Summary of the hazards with

protective means:

12

Shutdown and long storage

12

Rebuild instructions

13

Trouble shooting

14

Performance

VA10J&X | VS10C | VA10C

15

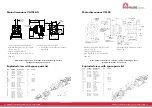

Main dimensions VA10J&X

16

Exploded view with spare parts list

16

Main dimensions VS10C

17

Exploded view with spare parts list

17

Main dimensions VA10C

18

Exploded view with spare parts list

18

ATEX Certification

19