10

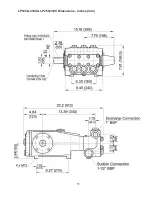

LP122A-3100 & LP250-3100 Torque Specifications

Pump Mounting Selection Guide

Bushings

06496

- 35mm H Bushing

Pulley & Sheaves

07165

- 12.75” Cast Iron - 4 gr. - AB Section

Rails

07357

- Plated Steel Channel Rails

(L=11.75”xW1.88”xH=3.00”)

Preventative Maintenance Check List & Recommended Spare Parts List

Check

Daily

Weekly

50 hrs

Every

500 hrs

Every

1500 hrs

Every

3000 hrs

Oil Level/Quality

X

Oil Leaks

X

Water Leaks

X

Belts, Pulley

X

Plumbing

X

Recommended Spare Parts

Oil Change p/n 01154

X

X

Seal Spare Parts (1 kit/pump)

(see page 5 for kit list)

X

Oil Seal Kit (1 kit/pump)

(see page 5 for kit list)

X

Valve Spare Parts (1 kit/pump)

(see page 5 for kit list)

X

Position Item #

Description

Lubrication

Info

Torque Amount

1

07759

Crankcase

Molycote Cu-Paste

6

05943

Oil Sight Glass w/Gasket

Loctite 572

29.5 ft.-lbs. (40 Nm)

10

01010-0100

Screw, Cover

18.5 ft.-lbs. (25 Nm)

12

07109-0400

Oil Drain Plug

29.5 ft.-lbs. (40 Nm)

17

07114-0100

Hex Screw, Bearing Cover

18.5 ft.-lbs. (25 Nm)

24

13277

Hex Screw, Connecting Rod

22.1 ft.-lbs. (30 Nm)

29C

07737-0100

Plunger Bolt

Loctite 243

25.8 ft.-lbs. (35 Nm)

31

07133

Radial Shaft Seal

Loctite 403

44

07748-0500

Valve Seat

Hylomar

48

06089

Plug, Valve

Loctite 243

107 ft.-lbs. (145 Nm)

49

07157

Stud Bolt

Loctite (270)

49A

06577

Nut, Stud Bolt

59 ft.-lbs. (80 Nm)