8) Take out the seal case (38) from the valve (if

necessary secure 2 screwdrivers in the front O-ring

groove to extract seal casing from valve casing).

Coat seals with silicon grease before installing.

Mounting surfaces of the crankcase

and the valve casing must be clean and free of

damage. The components must lie exactly and

evenly on one another. The same exactness ap

-

plies for all centering positions in the crankcase,

pressure and valve casing.

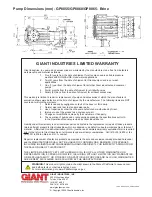

Pump Repair Instructions - GP8055/GP8060/GP8065 - Brine

7)

Be careful not to damage the seal

sleeve (39) and pressure ring (41). Check the inner

diameter of the pressure ring for wear and if neces

-

sary replace together with seals (40) and (42). Clean

all parts. New parts should be lightly coated with

silicon grease before installation. Inert the seal unit

(40, 41, 42 43) into the sleeve. Push the ceramic

plunger carefully through the seals from the crank

-

case side. If necessary, the seals can be held tightly

using a suitable pipe support held on the other side

of the seal sleeve.

9) Coat the seal sleeve lightly with anti-corrosive

grease (e.g. molycote no. Cu-7439) in its fitted area

towards the crankcase. Insert the seal sleeves in to

their crankcase fittings. Coat the threads of the ten-

sion screw (36C) lightly with thread glue and insert

it together with a new copper ring (36D) through

the ceramic pipe. Turn the pump per hand until the

plunger (25) rests against the plunger pipe. Tighten

the tension screw at 30 Ft-lbs.

Thread glue must never come between

the plunger pipe (36B) and centering sleeve (36E).

Overtensioning of the plunger pipe by excessive

tightening of the tension screw and/or dirt or damage

on the mounting surfaces can lead to plunger pipe

breakage. Insert the seal tension spring (45) and O-

ring (39A) in to the seal sleeve (39).

Replacing Valve Casing:

10) Put seal cases (38) in the centering holes of the

valve casing, then push valve casing carefully on to

centering studs (50A). Tighten hexagon screws (49A)

evenly and crosswise at 266 Ft.-lbs.

The torque tension on the screws

(49A) must be checked after 8-10 operating hours;

the pump must be at zero pressure. Thereafter,

the tension is to be checked every 200 operating

hours.

10