3

7. Maintenance and Servicing

For the type of thread lock used and the required

tightening torques, observe the table in the exploded

view.

7.1 Special tools required

The following special tools are required for

assembly:

- Pull-out tool ø24 mm

- Seal extractor tool ø22.4 mm

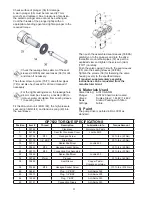

7.2 Suction and Discharge Valves

Remove hexagon screw (58) and remove valve

casing (54). Pull seal case (38) out of valve casing

(54). Pull valve body (52) and seal case (38) apart.

Using pliers, pull spring guide (55) out of the

valve casing. Remove discharge valve plate (57)

together with spring (56) from spring guide (55).

Check sealing surfaces of the valve body (52) and

discharge valve plate (57). Check discharge valve

spring (56) and border seal ring (53) and replace

where necessary.

A damaged border seal ring (53) must be

replaced before reassembling.

Suction Valves

Remove suction valve spring (50) with valve plate

(51) from seal case (38). Check sealing surfaces

of the valve plate (51) and valve body (52).

Check O-rings (38/A/B/C) and support ring

(38D) before reassembling. Worn parts must be

replaced

.

To Check Seals and Plungers

Unscrew hexagon screws (58), and take off valve

casing (54). Remove the screw-in joints (70) and

take off the elbow pipes (72). Pull seal sleeve

(39/39A) out of the crankcase.

Take the seal tension spring (40) out of seal

sleeve (39/39A).

Using a pliers, remove the clip ring (48) situated

on the other side of the sleeve; then take out

support ring (47) and grooved ring (46) using an

extractor tool (ø24).

Using a seal extractor tool (ø22.4), carefully press

the seal unit comprising guide ring (44), spiral

ring (42) and support ring (41/43) out of the seal

sleeve (39/39A) from the side (39/39A) closest to

the drive.

Check spiral ring (42),Support ring (43), guide

ring (44) and grooved ring (46) and replace where

necessary.