6

To Check Valves

Remove inner hexagon screw (48A) and remove plugs (48) with a screwdriver. Check O-rings on plugs (48B).

Pull out tension spring (48C). Take spacer pipe (46D) together with the discharge valve out of the valve casing

using a clipring pliers or a ø22 extractor tool. Remove the next exposed spacer pipe and suction valve as already

described. Remove the valve seats (46A) from the spacer pipes by lightly tapping the valve plate (46B) from

above with a plastic rod. Check sealing surfaces and replace worn parts.

When reassembling, use new O-rings if possible and oil them before installing.

Tighten inner hexagon screws (48A) to 35 Ft-Lbs (47NM).

To Check Seals and Plunger Pipe

Loosen the 8 nut and pull off valve casing to the front. Pull seal sleeves (35) out of guides in crankcase and over

the plunger pipe (29B). Pull support ring (41), sleeves (40) and pressure ring (39) out of seal sleeve.

Check plunger surfaces, sleeves (40) and grooved rings (36). Replace worn parts.

If the plunger pipe is worn out, loosen tension screw (29C) and pull off plunger pipe to the front. Clean contact

surfaces of plunger (25) thoroughly. Then place new plunger pipe carefully through the oiled seals into the seal

case. Check O-rings (35A, 35B) on seal sleeves and replace worn O-rings. Then push seal sleeve together with

plunger pipe into the crankcase guide. Turn gear carefully until plunger (25) comes up against the plunger pipe.

Put a new copper gasket (29D) onto the tension screw (29C). Cover the thread of tension screw and the gasket

with glue and tighten to 26 Ft.-lbs. (35NM).

Important!

Care must be taken that no glue gets between the plunger pipe (29B) and the centering sleeve

(29A). The plunger pipe should not be strained by eccentric tightening of the tension screw or through damage

to front of surface of plunger, otherwise it will probably break. Tighten the inner screws (49) for the valve casing

evenly to 74-89 Ft.-Lbs. (100-120NM).

To Dismantle Gear

Drain oil after dismantling valve case and plunger pipes and screw off crankcase cover (4) and bearing cover

(14).

Loosen con rod screws (24), push stem of con rod as far as possible into the crosshead guide and carefully

push out the radial shaft seals (31).

Important!

Connecting rods are marked for identification. Do not twist con rod halves. Con rod is to be reinstalled

in the same position on shaft journals.

While slightly turning the crankshaft, hit it out carefully to one side with a rubber hammer.

Important!

Do not bend con rod shank. Finally, check surfaces of shaft, con rod, crosshead and plungers (25)

as well as radial shaft seals (15, 31) and taper roller bearings (20).

To Reassemble

Using a soft tool, press in the outer bearing ring until it lines up with the outer edge of the bearing hole. Remove

bearing cover together with shaft ring and O-ring. Fit shaft with pressed-on bearing parts through the bearing

hole on the opposite side. Press in outer bearing ring and tension it inwards with the bearing cover, keeping the

shaft in vertical position and turning it slowly so that the taper rollers of the bearings touch the edge of the outer

bearing ring. Adjust axial bearing clearance with fitting discs 0.1mm (20A). Shaft should turn easily with very

little clearance. Tighten inner hexagon screws on con rod (24) to 26 Ft.-Lbs. (35NM).

Important!

There should be enough clearance for the con rod to move sideways a little on the journals.

Important!

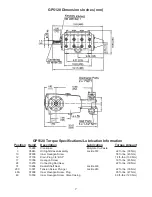

The 1/2” BSP connection in the crankcase serves the purpose of draining leakage water. The

connection should not be closed (see the drawing to the right).

GP5128 Repair Instructions

Summary of Contents for GP5128

Page 4: ...4 GP5128 Exploded View...