www.ghibliwirbel.com

Professional Cleaning Machines Since 1968

ENGLISH

- 7

20) Sensor for the start of the rotation of

the brush/es

• (for model with traction)

Acting on the touch sensor (20) with

button (45) “

” button (52) “

” and

button (51) “

” inserted it starts the

rotation of the brush and the water sup-

ply.

45) Main switch

“

”

By pressing the button, voltage is insert-

ed in the circuits allowing the operation

of commands and of the appropriate but-

tons; the display (46) will turn on.

Press the button again to disconnect the

voltage from the circuits.

46) Display

It lights up after the voltage is supplied to

the circuits using the button (45) “

”.

The display indicates the machine status,

battery charge, working hours and alarm

messages.

47) Speed control buttons

(for model with traction only)

Button (47a) “

”.

Pressed, increases the traction speed.

Button (47b) “

”.

Pressed, decreases the traction speed.

The display (46) indicates the set speed.

48) Reverse button “

”

(for model with traction only)

Check the display so that the minimum

traction speed is set.

Pressed and held, while action on the

touch sensor (20), the machine will move

in reverse to the operator. The display will

show the following symbol “R”. To move

in reverse, lift the wiper.

5.1.b - Charging the battery using an

external battery charger (Fig.

8)

WARNING:

It is important to first connect the plug (35)

to the socket (44) of the battery charger

and then connect the battery charger to

the mains socket, otherwise the batteries

will not charge.

- Move the machine close to the battery

charging station.

- Remove the battery plug (35) from the

system socket (39).

- Connect the battery plug (35) to the ex-

ternal battery charger socket (44).

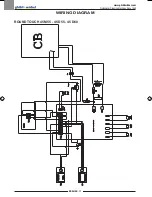

6.1 CONTROL PANEL

(Fig. 9)

WARNING:

Before using the machine you must se-

lect the washing cycle as shown in the

relevant paragraph.

20)Touch sensor for the start-up and ro-

tation of the brush/es

• (for model with traction)

Check the display so that the minimum

traction speed is set.

Acting on the touch sensor (20) with but-

ton(45) “

” button (52) “

” and but-

ton (51) “

” inserted, it starts the trac-

tion and rotation of the brush/es and the

water supply.

The machine will automatically start mov-

ing forward.

To move in reverse, lift the wiper.

MAN_ROUND45TOUCHECO_ed_02-2018_49026000.indd 7

28/02/18 11:38

Summary of Contents for Round 45 Touch 45D55

Page 4: ......

Page 6: ......

Page 30: ...www ghibliwirbel com Professional Cleaning Machines Since 1968 ENGLISH 24...

Page 31: ......