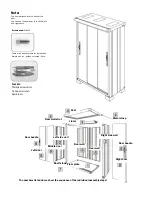

IMPORTANT INFORMATION

CHECKING PARTS LISTS

We strongly recommend checking the parts of the frame as well as the twin-wall sheets for completeness

on the basis of the parts list.

With the guarantee that all parts are completely available, a continuous structure is ensured and

you save time and hassle of having to stop assembly.

ATTENTION:

To rule out shortfalls as far as possible, we use the most modern weighing techniques, and the

individual packing steps are continuously and fully monitored by exact weight checks.

This allows us to largely rule out any shortages or any mixing up of parts.

However, if a part is damaged during transport, or if a part is missing, we will send it to you as quickly

as possible.

REQUEST:

The manufacturer / importer is GFP Handels GesmbH, Passauerstr. 24, A-4070 Eferding, Austria (hereinafter

also referred to as „the manufacturer“, „we“ or „us“).

If you have any questions about the assembly or the product itself, please contact the supplier

through whom you purchased your product.

Duration and commencement of the guarantee:

The guarantee for these metal products is granted for a

period of 20 years.

The guarantee covers rusting through of sheet metal parts

and parts which are demonstrably unusable or considerably

impaired in their usability due to faulty design or defective

workmanship. The period begins with the date of delivery.

Any replacement deliveries shall not result in an extension

of the guarantee period.

Guarantee conditions

• The assembly / installation was carried out competently

according to the enclosed assembly instructions

• The product has been used exclusively for its intended

purpose and within the scope of normal use.

• The product is owned by the original purchaser and has

not been disassembled and reassembled.

Guarantee coverage:

• The guarantee covers parts which are demonstrably

unusable or considerably impaired in their usability due

to faulty design or defective workmanship.

• Parts will be repaired or replaced free of charge at our

discretion.

• We do not cover the costs for removal, installation and

transport.

• Replaced parts either become the property of GFP or

are to be disposed of by the customer.

• GFP accepts no liability for any secondary damage.

Limitations of the guarantee:

This guarantee does not cover defects which are due to:

• transport damage (the carrier is liable for this - please

report immediately)

•

external influence or forces, extraordinary natural

phenomena (e.g. hail)

• general assembly errors

• defects with the foundation, lack of water drainage in

the area around the floor

• unsuitable installation site and/or lack of anchoring

• paint damage and scratches that are not immediately

repaired

• maintenance errors (e.g. not oiling/greasing the lock

and hinges).

• excessive levels of humidity or aggressive

environmental substances (e.g.: aggressive and

abrasive cleaning agents, road salt, fertilisers and

other chemical substances, salty and/or sandy local

conditions).

• wearing parts (e.g. door rollers, hinges, locks, etc.)

• colour changes, as dyes can change over time

• For rubber and plastic parts, only the statutory

guarantee period of 24 months applies.

Miscellaneous:

• The registered address for all liabilities arising from

guarantee obligations is A-4070 EFERDING.

• The buyer or a third party cannot derive any further

rights from this guarantee, in particular no claims for

damages of any kind or rights of offsetting or retention.

• The statutory guarantee claims remain unaffected by

this guarantee.

Guarantee policy