21

DANGER

Burns or intoxication from escaping

medium may cause extremely severe or

even fatal injuries.

Only insert new sight glasses in

perfect condition.

Clean all VAPOSCOPE components

before installation.

Remove foreign objects.

Tighten the hex nuts in the sight glass

lid evenly to the specified torque.

Check all removed parts for signs of damage.

Replace all worn or damaged parts.

Clean all dirty parts.

Coat the thread and contact surfaces with

temperature-resistant lubricant.

The lubricant must have the same properties as

OKS 217.

Insert the new inner sight glass seal.

Insert the new mica disc.

Insert the new sight glass.

Insert the new outer sight glass seal.

In type GK 21, insert the spherical washer in the

upper sight lass.

Insert the sight glass lid in the body.

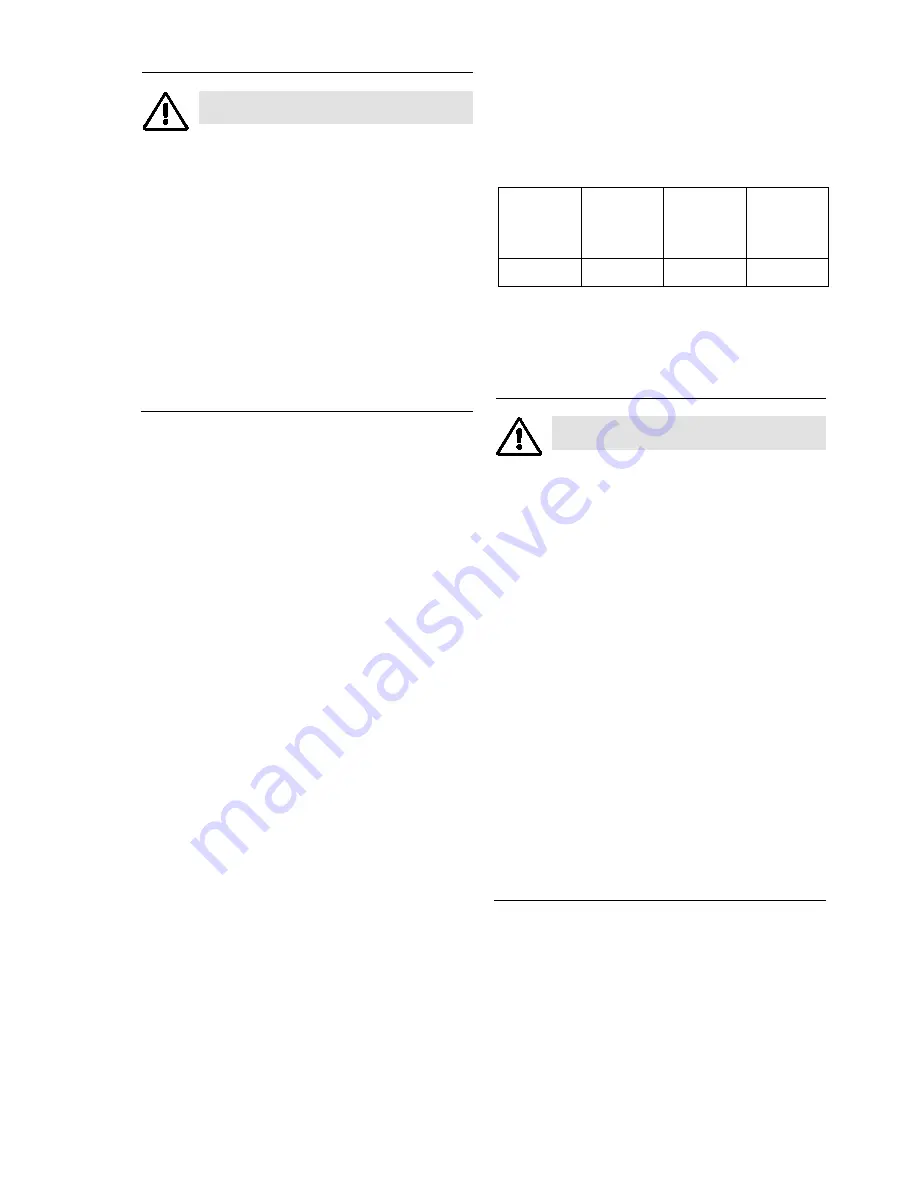

The necessary torque for tightening the hex nuts

varies depending on type.

Please refer to the following table for the correct

torque.

GK 21

DN50

GK 11

DN65,

DN80

GK 11

DN100

GK 11

DN150

25 Nm

30 Nm

90 Nm

90 Nm

Tighten the hex nuts to the specified torque.

Secure the second sight glass in the same way.

Removing the lid

DANGER

Personnel working on pipes are exposed to

safety risks and may suffer severe injuries,

poisoning or even loss of life.

Make sure that no hot or hazardous

fluid is in the equipment or the pipes.

Make sure that the pipes upstream

and downstream of the equipment are

depressurised.

Make sure that the installation is

switched off and protected against

unauthorised or unintended activation.

Make sure that the equipment and the

pipes have cooled down to room

temperatures.

Wear protective clothing that is

suitable for the fluid and, if necessary,

wear protective gear.

For more information on suitable protective clothing

and safety gear refer to the safety data sheet of the

fluid in question.

You require the following tools to remove and fit the

lid:

Combination wrench to DIN 3113, type B (size

17, 18, 19, 24 or 30, depending on equipment

type)

Torque wrench to DIN ISO 6789