Helpful Hints on blade tension

Determining correct blade tension is somewhat sub-

jective. It is learned through experience and is some-

what dependant on personal preference. A properly

tensioned blade will last longer and be much less like-

ly to break prematurely. If the blade tension is too

loose, you will notice that the blade will have a ten-

dency to drift or slip off-line when cutting and you may

also experience excessive vibration or unusual noise.

A blade that is too tight will break prematurely.

Assuming the blade has been properly installed in the

blade mounts, when the blade tension lever is pushed

fully back towards the rear of the saw, the blade should be properly tensioned.

Test the blade tension by lightly plucking on the blade, like you would a guitar string, with your finger. If the

blade is tight and tensioned correctly you will get a clear and even note. If so, you are ready to proceed to

operating and cutting with the saw. If not, for some cases after double checking that the blade is properly

installed in the blade mounts, further blade tension fine tuning can be made by adjusting the rear knob to raise

the upper arm slightly.

Note: this is not the main function of the adjustment knob (see following paragraph) and using

this knob as the primary blade tensioner will cause premature wear and damage to the machine.

This saw has an adjustment knob

I

in the rear that can raise the blade mount up to 1” (25 mm). This allows you

to fine tune blade tension when needed, as well as to reposition the saw blade at a point where you can use

a different part of the blade in the cutting area. This also allows you to use a piece of band saw blade, cut to

a length of 5”- 6” (127-150 mm) in your saw, and gives you up to 3 inch cutting capacity when needed.

Note: Do not over tension the knob as this can cause premature wear and damage to the machine.

INSTALLING OR CHANGING BLADES

ALWAYS TURN OFF AND UNPLUG THE MACHINE

BEFORE REMOVING, HANDLING OR CHANGING

BLADES.

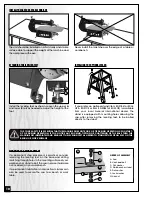

1.

Remove an installed, worn or broken blade by flip-

ping the blade tension lever forward (position

1

), then

loosening the thumbscrews

A

and

B

on the upper

and lower blade mounts.

2.

Remove the blade.

3.

Verify that the upper arm is more or less parallel (with-

in 1/8”) to the saw table. If necessary, use the upper

arm adjuster

I

(section in gray below) to raise or

lower the arm as needed.

4.

With the blade teeth facing forward and downward

slip the bottom of the blade down through the hole in

the table. Then slip the upper end of the blade into

the slot in the upper blade mount and position the

top of the blade above the set screw

C

but no higher

than the top of the shoulder

D

on the blade mount.

Then tighten the thumbscrew only enough to secure

the blade in the mount and prevent it from slipping

out.

5.

The bottom portion of the blade may protrude be-

yond the bottom of the lower blade mount, this is

normal and will not affect performance. Only the up-

per portion of the blade requires proper positioning

in the upper blade mount.

Note: Overtightening the blade clamp thumbscrews can cause

premature wear to the blades gripping surface and result in blade

slippage or cause premature wear of the threads in the blade

clamp housing.

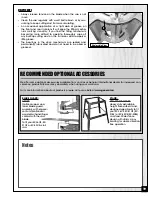

To avoid kinking or damaging the blade in the holder,

E,

when

making adjustments make sure the set screw

F

(opposite the

thumbscrew G) is threaded into the holder to protrude slightly

beyond the blade slot

H

.

6.

Push the blade tension lever back (position

2

) to apply

tension on the blade.

G

F

H

E

C

D

Position

blade

between

these points

Upper arm must be parallel

(approx. 1/8”) to the table

1

2

RAISE

I

LOWER

13

A

B