Gen-Eye SD™ Video Pipe Inspection/Location System

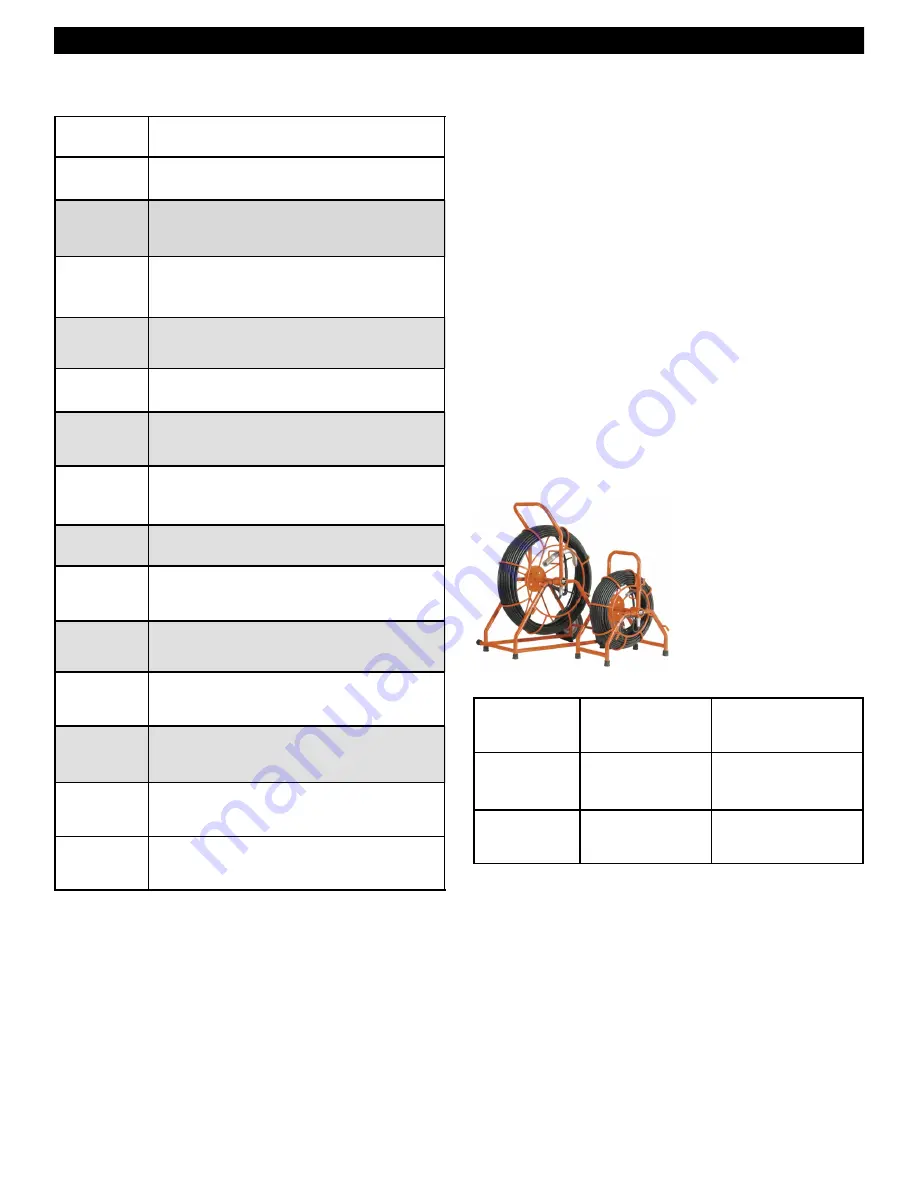

Table 1—Reel Selection Guide

Reel Type

Pipe Sizes

Lengths

Available

Standard

Reel

3‖ to 10‖

(75 to 300mm)

200, 300. or 400 ft.

(60, 90 or 120m)

Mini Reel

1-1/2‖ to 4‖

(38 to 100mm)

100 or 200 ft.

(30 or 60m)

SKIDS

Depending on the size of pipe you are inspecting, you

may need to use the supplied skid so the camera is cen-

tered of off the bottom of the pipe. Care should be taken

so the skids do not snag in the pipe.

Under normal operating situations, the camera is used

with the smaller protective sleeve in 4‖ lines or the larger

finned sleeve in 6‖ and larger pipes.

The skids supplied should be slipped onto the camera

with the lip of the sleeve at the front. Make sure the cam-

era body is clean and the set screws tightened only until

they touch the camera body. Do not over tighten as you

may damage the camera housing.

KEY

FUNCTION

F1

Cursor ON/OFF

F2

Clear screen and place cursor at home

position (i.e. top left corner)

F4

Press [F4] followed by [+] or [-] and five

digits. Press [ENTER] to confirm

F5

Save current on-screen text to memory

page

F6

Time and Date ON/OFF toggle

[ENTER]

Move cursor to next line

Backspace erases letter and goes back

one position.

[ESC]

[ESC] followed by 1-9 recalls saved

pages on screen

[CTRL]-D

Set Time/Date. [ENTER] to quit

[CTRL]-C

Reposition counter in one of the four cor-

ners and the bottom center of the screen

[CTRL]-B

Type black characters with white border

[CTRL]-F

Turn flashing characters ON

[CTRL]-N

Turn flashing characters OFF

[CTRL]-W

Type white characters

KEYBOARD/COUNTER OPERATING

INSTRUCTIONS

SETTING TIME/DATE

Hold [CTRL] and press D. ―YYMMDDHHMMSSam‖ ap-

pears on the screen. Type in the correct time and date in

this order: year, month, day, hour, minutes, seconds, am/

pm (a for AM and p for PM). If you wish to quit, simply hit

the [ENTER] button and date and time entry line will dis-

appear.

(Note that the clock mode is 12 hour—i.e. 01 to 12.)

SAVING A PAGE

To save a page to memory, go to the page you wish to

save by pressing [ESC} followed by 1-9 (ex. [ESC]+[5]).

Type text on screen. Press [F5] to save screen text to

selected page.

6

COUNTER SET UP

Before starting the inspection, and only after you have

placed the camera in the line, you should make sure to

zero your counter. This is your starting point for measure-

ments.

TO SET THE COUNTER

To set the counter to a preset value, press the F4 key.

Then press either ―+‖ or ―-‖ followed by five digits

(numbers). To set the counter to +0000.0 press [F4] fol-

lowed by [ENTER].