12 / 16

687

16. Insert new upper sealing washer

22

.

17. Insert upper membrane plate

6

-

observe correct installation position

(see drawing chapter 5).

18. Insert washer

9

.

19. Tighten new hexagon nut

21

with an

open-end wrench SW13 with 16 Nm.

20. Remove compression spring

32

from

actuator base

16

.

21. Remove bush

17

.

CAUTION

Damage to the bush guide in the

actuator base 16 when using

unsuitable tools!

®

Damaged bush guide can no

longer ful

fi

l its function.

G

Press out bush

17

from actuator

base

16

upwards with an

appropriate tool that will not

damage the bush guide.

22. Press in new bush

17

.

CAUTION

Damage to the bush 17 when

using unsuitable tools!

®

Damaged bush

17

can no longer

ful

fi

l its function.

G

Press bush

17

from above

into actuator base

16

with an

appropriate tool that will not

damage bush

17

.

23. Insert new compression spring

32

into

actuator base

16

.

24. Lubricate actuator spindle

15

(GEMÜ recommends MOLYCOTE 111

COMPOUND).

25. Insert the actuator membrane assembly

manually into actuator base

16

from

above through bush

17

and push

it down. The actuator membrane

assembly comprises actuator

spindle

15

including dowel pin

30

and

adapter

31

, hexagon nut

21

, washer

9

,

upper membrane plate

6

, upper sealing

washer

22

, actuator membrane

14

,

lower sealing washer

22

, distance

piece

28

(only for diaphragm sizes 40

and 50), O-ring

27

(only for diaphragm

sizes 40 and 50) and lower membrane

plate

6

.

26. Take care that the hole patterns of

actuator membrane

14

and actuator

base

16

are aligned.

27. Assemble the actuator as described in

chapter 5.3, points 1-11.

5.3 Assembly of actuator

1. Put on actuator top

10

, take care that

the hole patterns of actuator top

10

,

actuator membrane

14

and actuator

base

16

are aligned.

2. Clamp actuator in a press.

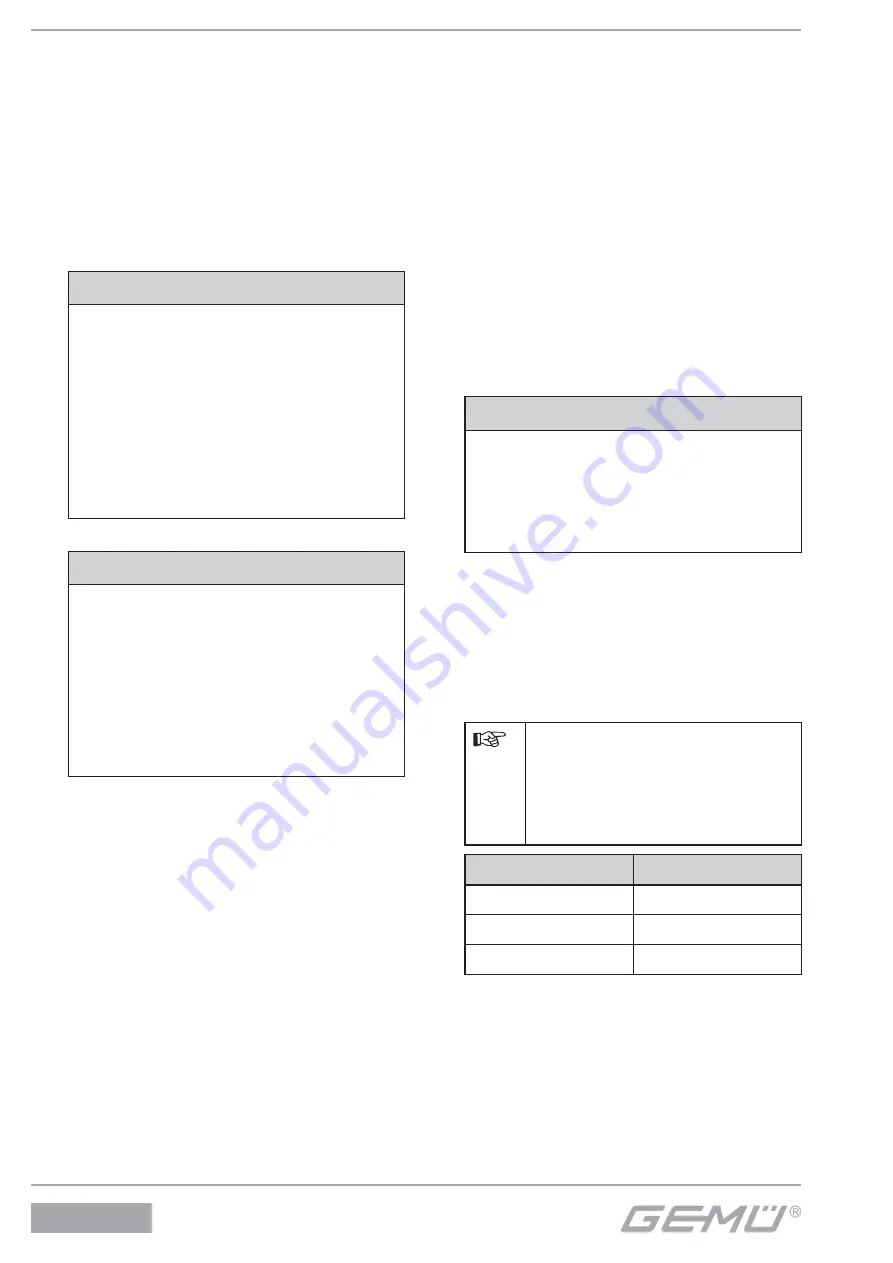

CAUTION

Applied pressure too high!

®

Risk of breakage of actuator

top

10

!

G

Only use minimum required

pressure.

3. Diaphragm sizes 25 and 40:

Bolt together diagonally actuator top

10

and actuator base

16

with bolts

12

.

Diaphragm size 50:

Bolt together diagonally actuator top

10

and actuator base

16

with bolts

12

and

nuts

35

.

Important:

The bolts

12

between actuator

top

10

and actuator base

16

are always inserted from

above.

Diaphragm size

Tightening torque

25

6 Nm

40

15 Nm

50

21 Nm

4. Slowly release the press.

5. Put protective caps

29

onto bolts

12

.

6. Diaphragm size 50:

Put protective caps

34

onto nuts

35

.

7. Reinsert loose compressor

3

.

8. Lubricate new O-ring

44

(GEMÜ recommends MOLYCOTE 111

COMPOUND).

Summary of Contents for 687

Page 14: ...14 16 687...

Page 15: ...15 16 687...