14

3.5. Operating

The winches are suitable for manual operation only.

For the load to be hoisted, turn the crank clockwise.

For the load to be lowered, turn the crank anticlockwise.

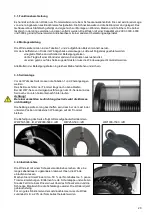

4. Maintenance

The winch must be unloaded for inspection and maintenance tasks.

Inspection and maintenance tasks must be performed by skilled personnel, e.g. via your Gebuwin

dealer.

Inspection/ Maintenance

interval

Tasks

Before each use

-

visually check cable and loading hook

-

check amount of grease* on the worm wheel gearing

-

check the brake function

Per quarter

-

visually check cable and loading hook for any fracture

-

grease the worm - worm wheel gearing

-

check the load pressure brake for wear and tear

Replace the brake discs as needed

Be careful: Do not get any grease on the brake discs or preceding

surfaces

Annually

-

check the cable according to DIN 15020 pg. 2 for wear and tear; also

test and maintain the minimum breaking force.

-

check the tightness of the mounting bolts

-

check all the winch parts for wear and tear; replace where necessary;

grease where needed.

-

check the type identity sticker for clarity

* Texaco “Texclad premium 2” is recommended by us for the worm - worm wheel gearing (or equivalent).

Orders can be placed through your Gebuwin dealer or on the website:

5. Troubleshooting

Trouble/Malfunction

Cause

Solution

The unloaded winch rotates

heavily

-

no grease on the gearing

-

dirt on the gearing

-

during mounting the winch has

pulled askew

-

apply grease

-

clean with a detergent and re-

grease

-

level the mounting surface and re-

mount the winch

The load cannot be held

-

the cable has been incorrectly

wound round the drum which

means the crank turning

direction is incorrect

-

the brake discs are either worn

down or faulty

-

wind the cable correctly around

the drum

-

check and/or renew the brake

discs

The load pressure brake does

not function

-

braking mechanism and/or discs

are jammed due to infrequent

use

-

loosen the brake by hitting the

crank in the correct turning

direction with the flat of the hand

Summary of Contents for WW1000 D/Ex Series

Page 2: ...1...