2

09665

-01

.2

01

9-

Gb

About these instructions

Read these instructions before assembly and before using the

compressor. This will avoid misunderstandings and prevent dam-

age. Improper assembly and use of the compressor can result

in serious or fatal injury.

Observe the safety instructions contained in these instructions.

Liability and warranty

Manufacturer‘s liability and warranty are excluded if

• Alterations and functional modifications have been carried out

• No original replacement parts have been used

Contents

Page

1 Introduction

3

2 Safety

3

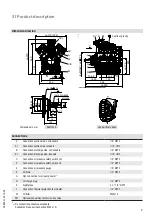

3 Product description

5

4 Technical data

8

5 Maintenance

9

6 Fault diagnosis

11

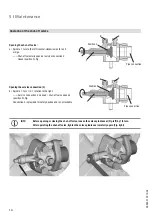

7 Installation of service kits

15

8 Electromagnetic coupling

21

9 Compressor defects

23

10 Disassembly of the compressor

24

11 Checking the compressor parts

37

12 Assembly of compressor

40

13 Parts list

54

14 Exploded drawing

58

Contact

GEA Bock GmbH

Benzstraße 7

72636 Frickenhausen

Germany

Telephone +49 7022 9454 0

Fax

+49 7022 9454 137

[email protected]

www.gea.com