– 14 –

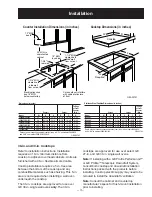

Pan Detection

The pan detection system includes a pan sensor,

an inductive sensor interface chip (ISIC) perma-

nently mounted on the logic board, and a signal

wiring harness connecting the sensor with the

ISIC.

GEA00766

Temperature Sensor

Temperature Sensor

Temperature Sensor

Sensor Connectors

Sensor Connectors

Sensor Connectors

Logic Board

Logic Board

Heater

Heater

Pan Sensor

Pan Sensor

The pan sensor determines the presence or

absence of a pan through a change in the mag-

netic field. When a metal pan is near the sensor,

the resonant frequency of the pan increases. This

information is passed to the ISIC, which deter-

mines a pan to be present. When the frequency

drops to a specified level, the ISIC determines the

pan to

not be present and turns the surface

element OFF after 1 minute.

Pan Size Feature

When the pan detection feature is active, the pan

size feature is also active. The pan size feature is

designed to automatically recognize the size of a

pan placed on the dual heater and energize one or

both cooking zones to match the size of the pan.

The pan size feature is overriden when the DUAL

key is pressed.

Technician Mode

To enter the Technician Mode, lock the cooktop by

holding the CONTROL LOCK key for 3 seconds.

The control will beep 2 times and the word

LOCK

will be displayed in the timer display. Press the

timer ON/OFF key and simultaneously press the +

keys of the LF and LR surface elements. The timer

display will flash

TECH MODE when the cooktop

is in Technician Mode.

To exit the Technician Mode, simultaneously press

the timer ON/OFF key and the (+) keys of the LF

and LR surface elements, or unlock the cooktop

by holding down the CONTROL LOCK key for 3

seconds. The control will beep 2 times and the

CONTROL LOCK LED will turn OFF.

Summary of Contents for Profile JP938

Page 19: ...17 Fault Code Behavior Table...

Page 33: ...31 Notes...

Page 34: ...32 Parts List...

Page 36: ...34...

Page 38: ......

Page 39: ......