Design Guide

6

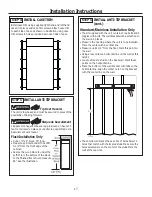

These units are equipped with a 3-position door stop.

The factory set 115° door swing can be adjusted to 90°

if clearance to adjacent cabinets or walls is restricted.

Order WX14X99 door stop for precise settings between

90° and 115°.

When Installed into a corner:

Allow 15” for a full 115° door swing and pan removal.

Allow 4” min. clearance when door swing is adjusted

to a 90° opening for pan access, but pan removal is

restricted.

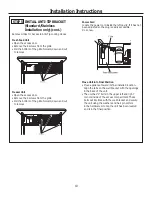

CLEARANCES FOR FLUSH INSTALLATION ONLY

ZUGF2 Unified Grille Panel Kit

• If you are installing two units, side by side,

the installation space must be 75-1/2” wide.

Note: Additional cutout width may be required when

side panels are used. Add side panel thickness

to the finished cutout to calculate rough-in width.

• The water and electrical locations for each product

must be located as shown.

• A separate 115V, 60Hz., 15 or 20 amp power supply

is recommended for each product.

75-1/2" Finished Width

2-5/16"

24-3/16"

9"

5"

5"

5"

5"

5-1/2"

9"

5-1/2"

Electrical

Electrical

Area

Cold Water

Supply

Wall View

Cold Water

Supply

24" Minimum

Cutout Depth

84-1/2" Max

Finished

Opening

3-1/2"

3-1/2"

3-1/2"

3-1/2"

3-1/2"

3-1/2" 3-1/2"

3-1/2"

3-1/2"

3-1/2"

Clearances for Multiple Single Door Installations

In a side-by-side installation of a left and right door

swing product, a 1-1/2” clearance between the units is

required. Order ZUGF2 Unified Grille Panel Kit for one

continuous grille panel.

15"

Min. to

Wall

15"

Min. to

Wall

115° Door

Swing

1-1/2"

115° Door

Swing

Clearances for two products installed side-by-side

with the same (left or right) door swing

Allow 2” minimum clearance between the products

to prevent door swing interference. Order the WX14X99

adjustable door stop to reduce the factory set 115°

door swing. Allow 15” minimum to a wall to achieve

full drawer extension and pan removal.

NOTE: ZUG2 and ZUGSS2 Grille Panel Kit will NOT fit this

installation.

4"

15"

Clearances for two products installed side-by-side

with right and left side hinges together

Allow 5” minimum between the two products to prevent

one door from striking the other. Use the WX14X99

adjustable door stop to reduce the factory set 115°

door swing and to allow pan removal.

NOTE: ZUG2 and ZUGSS2 Grille Panel Kit will NOT fit this

installation.

5"

FLUSH INSTALLATION ONLY

Summary of Contents for Monogram ZIRS360NNLH

Page 30: ...Notes 30...

Page 31: ...Notes 31...