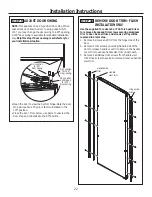

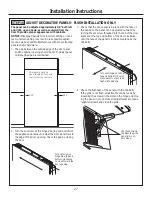

• Gently pull back at the ends of the plastic straps to make

the channel rest flush behind the wall.

• Hold the ends of the straps in one hand and slide the plas-

tic cap along the straps until the flange of the cap is flush

with the wall.

• Place your thumb between the plastic straps and bend up

and down to snap the straps off at the wall.

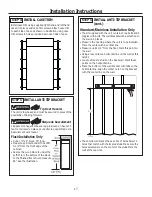

Install Screws and Bolts:

• Have someone hold the wall bracket centered in place

with each of the holes aligned with the correct opening in

the bracket and level with the horizontal line.

• Insert the lag screws through the bracket and into the

stud. Tighten with a wrench.

•

Insert the bolts into the toggle by hand until snug.

Tighten with a wrench.

Anti-Tip Wall Bracket

Bolt

Wall Toggle

Drywall or

Steel Stud

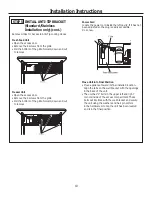

• Mark an additional hole at each end of the bracket. If one

of the studs is closer to the end of the bracket, mark an

additional hole towards the center of the bracket.

• Drill 1/2” holes into the wall board at the locations marked

for the toggles to be mounted (not the stud markings).

• Drill 3/16” holes into wooden studs where marked. If steel

stud construction, drill 1/2” holes into the studs where

marked. You will use 2 toggles with the metal studs.

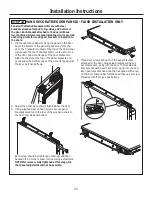

Install Wall Toggles:

The wall toggles and bolts can be ordered as Service Kit

#WR49X10193. Wall toggles are installed in the drywall

and metal studs for stability. Install the wall toggles as fol-

lows:

• Drill 1/2” holes at the wall markings made in the holes at

the ends of the wall bracket.

• Hold the metal channel flat against the plastic straps

and slide the channel through the hole.

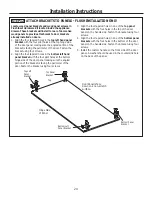

Installation Instructions

18

Plastic Straps

Metal Channel

Wood Stud

Lag Screw

Anti-Tip Wall Bracket

Two Additional

Hole Locations at

Ends of Brackets

Center

Wall Bracket

Line On Wall

Wall Studs

Line on Wall

Center

Cap

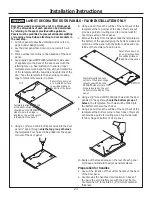

STEP 5 INSTALL ANTI-TIP BRACKET

(Standard/Stainless Installation

only) (cont.)

Summary of Contents for Monogram ZIRS360NNLH

Page 30: ...Notes 30...

Page 31: ...Notes 31...